Well-designed Tinned Copper Sheet - Brass Strip – CIVEN

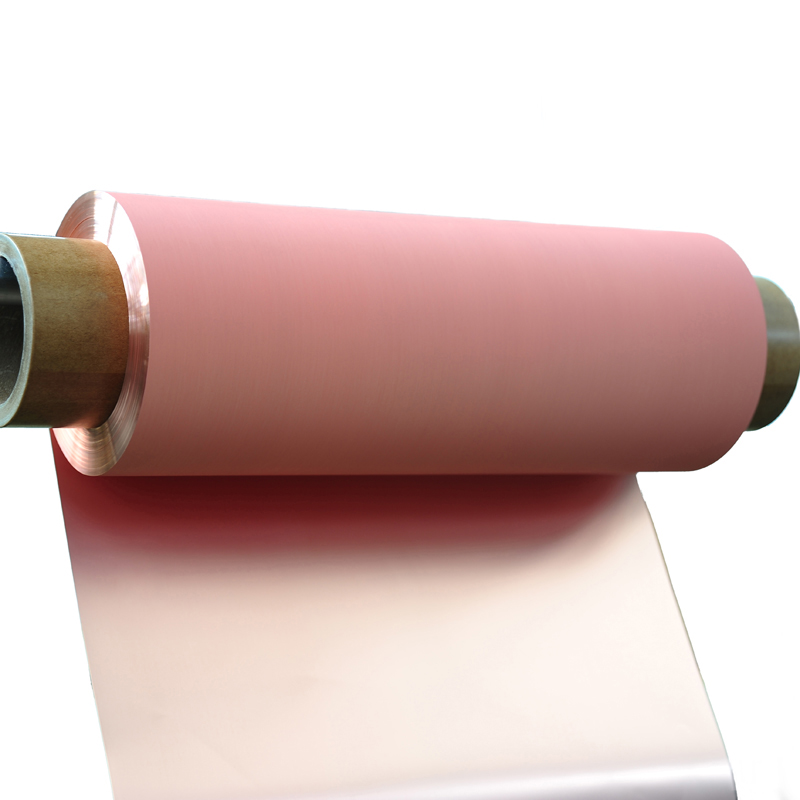

Well-designed Tinned Copper Sheet - Brass Strip – CIVEN Detail:

Product Introduction

Brass strip based on electrolytic copper, zinc and trace elements as its raw material, through processing by ingot, hot rolling, cold rolling, heat treatment, surface cleaning, cutting, finishing, and then packing.

Material processes performance, plasticity, mechanical properties, corrosion resistance, performance and good tin.

It has been widely used in electrical, automotive, communications, hardware, decoration and other industries.

Our company developed a product range for special-use, such as dry-type transformers strips,

the RF coaxial cable strips, shield strips to wire and cable, lead frame materials, punching strips for electronics,

solar photovoltaic ribbons, decorated with bronze doors, composite materials, car tank strips, radiator strips,

button band, musical instruments strip, sanitary ware strip, etc.

Main Technical Parameters

2-1Chemical Composition

|

Alloy No. |

Chemical Composition( %,Max.) |

||||||||

|

Cu |

Fe |

Pb |

Al |

Mn |

Sn |

Ni |

Zn |

Impurity |

|

|

H96 |

95.0-97.0 |

0.10 |

0.03 |

— |

— |

— |

0.5 |

Rem |

0.3 |

|

H90 |

88.0-91.0 |

0.10 |

0.03 |

— |

— |

— |

0.5 |

Rem |

0.3 |

|

H85 |

84.0-86.0 |

0.10 |

0.03 |

— |

— |

— |

0.5 |

Rem |

0.3 |

|

H70 |

68.5-71.5 |

0.10 |

0.03 |

— |

— |

— |

0.5 |

Rem |

0.3 |

|

H68 |

67.0-70.0 |

0.10 |

0.03 |

— |

— |

— |

0.5 |

Rem |

0.3 |

|

H65 |

63.5-68.0 |

0.10 |

0.03 |

— |

— |

— |

0.5 |

Rem |

0.3 |

|

H63 |

62.0-65.0 |

0.15 |

0.08 |

— |

— |

— |

0.5 |

Rem |

0.5 |

|

H62 |

60.5-63.5 |

0.15 |

0.08 |

— |

— |

— |

0.5 |

Rem |

0.5 |

2-2 Alloy Table

|

China |

ISO |

ASTM |

JIS |

|

H96 |

CuZn5 |

C21000 |

C2100 |

|

H90 |

CuZn10 |

C22000 |

C2200 |

|

H85 |

CuZn15 |

C23000 |

C2300 |

|

H70 |

CuZn30 |

C26000 |

C2600 |

|

H68 |

—— |

——- |

—— |

|

H65 |

CuZn35 |

C27000 |

C2700 |

|

H63 |

CuZn37 |

C27200 |

C2720 |

|

H62 |

CuZn40 |

C28000 |

C2800 |

2-3 Features

2-3-1 Specification Unit:mm

|

Name |

Alloy No.(China) |

Temper |

Size(mm) |

|

|

Thickness |

Width |

|||

|

Brass Strip |

H62 H63 H65 H68 H70 H85 H90 H96 |

O 1/4H 1/2H H EH |

0.05~0.2 |

≤600 |

|

>0.2~0.49 |

≤800 |

|||

|

0.5~2.0 |

≤1000 |

|||

|

Car Tank Strip |

H65 H68 |

O |

0.7~1.2 |

100~800 |

|

Radiator Strip |

H62 H70 H90 |

O 1/2H H |

0.05~0.20 |

20~600 |

|

Capacitor Strip |

H62 H65 |

1/2H H |

0.10~1.0 |

20~800 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

2-3-2 Tolerance Unit: mm

|

Thickness |

Width |

|||||

|

Thickness Allow Deviation ± |

Width Allow Deviation ± |

|||||

|

<600 |

<800 |

<1000 |

<600 |

<800 |

<1000 |

|

|

0.1~0.3 |

0.008 |

0.015 |

—– |

0.3 |

0.4 |

—– |

|

0.3~0.5 |

0.015 |

0.020 |

—– |

0.3 |

0.5 |

—– |

|

0.5~0.8 |

0.020 |

0.030 |

0.060 |

0.3 |

0.5 |

0.8 |

|

0.8~1.2 |

0.030 |

0.040 |

0.080 |

0.4 |

0.6 |

0.8 |

|

1.2~2.0 |

0.040 |

0.045 |

0.100 |

0.4 |

0.6 |

0.8 |

2-3-3 Mechanical Performance

|

Temper |

Tensile Strength N/mm2 |

Elongation ≥% |

Hardness HV |

|

|

M |

(O) |

≥290 |

35 |

—— |

|

Y4 |

(1/4H) |

325-410 |

30 |

75-125 |

|

Y2 |

(1/2H) |

340-470 |

20 |

85-145 |

|

Y |

(H) |

390-630 |

10 |

105-175 |

|

T |

(EH) |

≥490 |

2.5 |

≥145 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Well-designed Tinned Copper Sheet - Brass Strip – CIVEN , The product will supply to all over the world, such as: Czech Republic, Colombia, Namibia, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to supply the high-quality goods and services, and promote lasting cooperation with our customers, common development and create a better future.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!