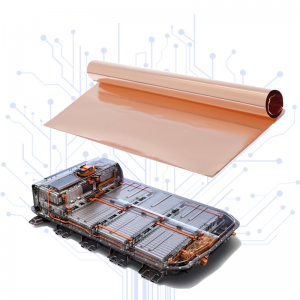

Tin Plated Copper Foil

Product Introduction

Copper products exposed in the air are prone to oxidation and the formation of basic copper carbonate, which has high resistance, poor electrical conductivity and high power transmission loss; after tin plating, copper products form tin dioxide films in the air due to the properties of tin metal itself to prevent further oxidation.

Base Material

● High-precision Rolled Copper Foil, Cu(JIS: C1100/ASTM: C11000) content more than 99.96%

Base Material Thickness Range

● 0.035mm~0.15mm (0.0013 ~0.0059inches)

Base Material Width Range

● ≤300mm (≤11.8 inches)

Base Material Temper

● According to customer requirements

Application

● Electrical appliances and electronics industry, civil (such as: beverage packaging and food contact tools);

Performance Parameters

|

Items |

Weldable Tin Plating |

Non-weld Tin Plating |

|

Width Range |

≤600mm (≤23.62inches) |

|

|

Thickness Range |

0.012~0.15mm (0.00047inches~0.0059inches) |

|

|

Tin layer Thickness |

≥0.3µm |

≥0.2µm |

|

Tin Content of Tin Layer |

65~92%(Can adjust tin content according to customer welding process) |

100% Pure Tin |

|

Surface Resistance of Tin Layer (Ω) |

0.3~0.5 |

0.1~0.15 |

|

Adhesion |

5B |

|

|

Tensile Strength |

Base Material Performance Attenuation after Plating ≤10% |

|

|

Elongation |

Base Material Performance Attenuation after Plating ≤6% |

|