Special Design for Flexible Circuit Board Copper Foil - HTE Electrodeposited Copper Foils for PCB – CIVEN

Special Design for Flexible Circuit Board Copper Foil - HTE Electrodeposited Copper Foils for PCB – CIVEN Detail:

Product Introduction

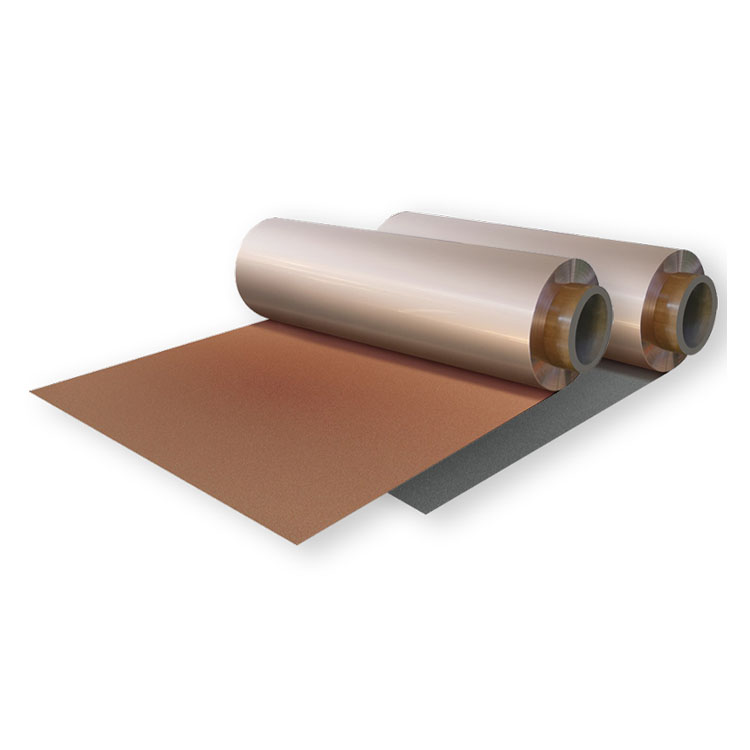

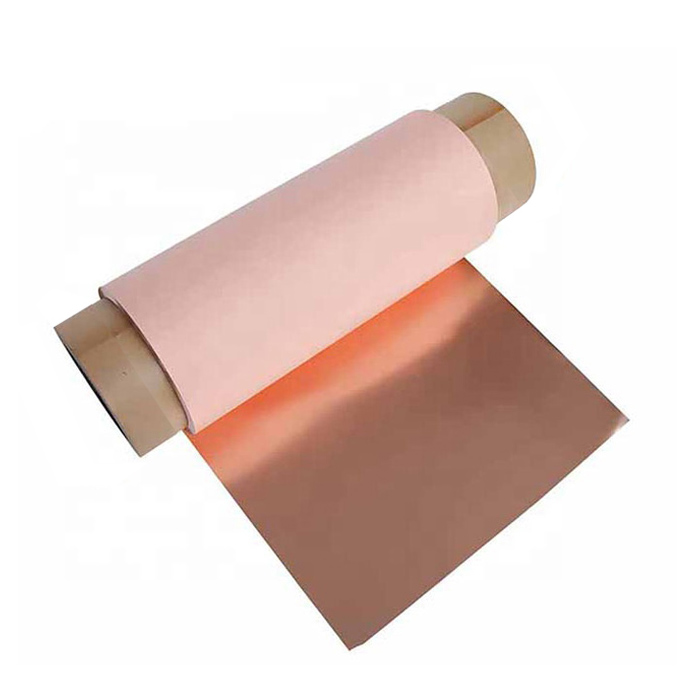

The electrolytic copper foil produced by CIVEN METAL has excellent resistance to high temperatures and high ductility. The copper foil does not oxidize or change color at high temperatures, and its good ductility makes it easy to laminate with other materials. The copper foil produced by the electrolysis process has a very clean surface and a flat sheet shape. The copper foil itself is roughened on one side, which makes it easier to adhere to other materials. The overall purity of the copper foil is very high, and it has excellent electrical and thermal conductivity. In order to meet the needs of our customers, we can provide not only rolls of copper foil, but also customized slicing services.

Specifications

Thickness: 1/4OZ~20OZ(9µm~70µm)

Width: 550mm ~1295mm

Performance

The product has excellent room temperature storage performance, high temperature oxidation resistance performance, product quality to meet the IPC-4562 standard Ⅱ, Ⅲ level requirements.

Applications

Suitable for all kinds of resin system of double-sided, multilayer printed circuit board.

Advantages

The product adopts a special surface treatment process to improve the product’s ability to resist bottom corrosion and reduce the risk of copper residue.

Performance(GB/T5230-2000、IPC-4562-2000)

|

Classification |

Unit |

1/4OZ (9μm) |

1/3OZ (12μm) |

J OZ (15μm) |

1/2OZ (18μm) |

1OZ (35μm) |

2OZ (70μm) |

|

|

Cu Content |

% |

≥99.8 |

||||||

|

Area Weigth |

g/m2 |

80±3 |

107±3 |

127±4 |

153±5 |

283±5 |

585±10 |

|

|

Tensile Strength |

R.T.(25℃) |

Kg/mm2 |

≥28 |

≥30 |

||||

|

H.T.(180℃) |

≥15 |

|||||||

|

Elongation |

R.T.(25℃) |

% |

≥4.0 |

≥5.0 |

≥6.0 |

≥10 |

||

|

H.T.(180℃) |

≥4.0 |

≥5.0 |

≥6.0 |

|||||

|

Roughness |

Shiny(Ra) |

μm |

≤0.4 |

|||||

|

Matte(Rz) |

≤5.0 |

≤6.0 |

≤7.0 |

≤7.0 |

≤9.0 |

≤14 |

||

|

Peel Strength |

R.T.(23℃) |

Kg/cm |

≥1.0 |

≥1.2 |

≥1.2 |

≥1.3 |

≥1.8 |

≥2.0 |

|

Degraded rate of HCΦ(18%-1hr/25℃) |

% |

≤5.0 |

||||||

|

Change of color(E-1.0hr/190℃) |

% |

Good |

||||||

|

Solder Floating 290℃ |

Sec. |

≥20 |

||||||

|

Pinhole |

EA |

Zero |

||||||

|

Preperg |

—- |

FR-4 |

||||||

Note: 1. The Rz value of copper foil gross surface is the test stable value, not a guaranteed value.

2. Peel strength is the standard FR-4 board test value (5 sheets of 7628PP).

3. Quality assurance period is 90 days from the date of receipt.

Product detail pictures:

Related Product Guide:

We have been ready to share our knowledge of advertising and marketing worldwide and recommend you suitable products and solutions at most competitive price ranges. So Profi Tools supply you best benefit of money and we're ready to create with each other with Special Design for Flexible Circuit Board Copper Foil - HTE Electrodeposited Copper Foils for PCB – CIVEN , The product will supply to all over the world, such as: Canada, Mozambique, Czech Republic, "Good quality and reasonable price" are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.