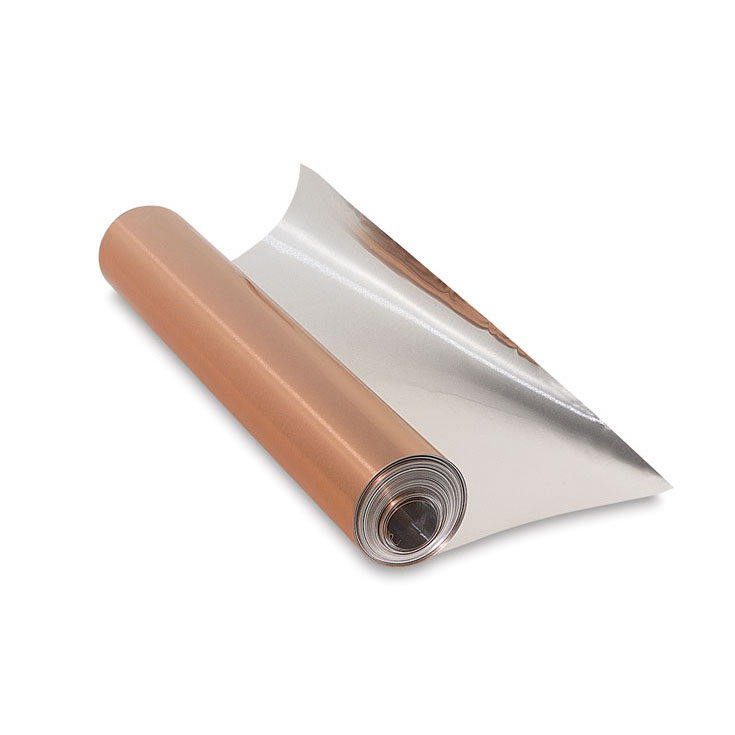

Short Lead Time for Battery Copper Foil - Tin Plated Copper Foil – CIVEN

Short Lead Time for Battery Copper Foil - Tin Plated Copper Foil – CIVEN Detail:

Product Introduction

Copper products exposed in the air are prone to oxidation and the formation of basic copper carbonate, which has high resistance, poor electrical conductivity and high power transmission loss; after tin plating, copper products form tin dioxide films in the air due to the properties of tin metal itself to prevent further oxidation. Tin can also form a similar film in halogen, so that the copper products after plating have good corrosion resistance and weldability, and at the same time have a certain strength and hardness, so they are widely used in electrical and electronic industry products; because tin metal is non-toxic and tasteless, the products after plating are also widely used in the food industry. The tinned copper foil produced by CIVEN METAL has a good surface finish and uniform tin layer thickness. They can be annealed and slit according to customer requirements.

Base Material

● High-precision Rolled Copper Foil, Cu(JIS: C1100/ASTM: C11000) content more than 99.96%

Base Material Thickness Range

● 0.035mm~0.15mm (0.0013 ~0.0059inches)

Base Material Width Range

● ≤300mm (≤11.8 inches)

Base Material Temper

● According to customer requirements

Application

● Electrical appliances and electronics industry, civil (such as: beverage packaging and food contact tools);

Performance Parameters

|

Items |

Weldable Tin Plating |

Non-weld Tin Plating |

|

Width Range |

≤600mm (≤23.62inches) |

|

|

Thickness Range |

0.012~0.15mm (0.00047inches~0.0059inches) |

|

|

Tin layer Thickness |

≥0.3µm |

≥0.2µm |

|

Tin Content of Tin Layer |

65~92%(Can adjust tin content according to customer welding process) |

100% Pure Tin |

|

Surface Resistance of Tin Layer (Ω) |

0.3~0.5 |

0.1~0.15 |

|

Adhesion |

5B |

|

|

Tensile Strength |

Base Material Performance Attenuation after Plating ≤10% |

|

|

Elongation |

Base Material Performance Attenuation after Plating ≤6% |

|

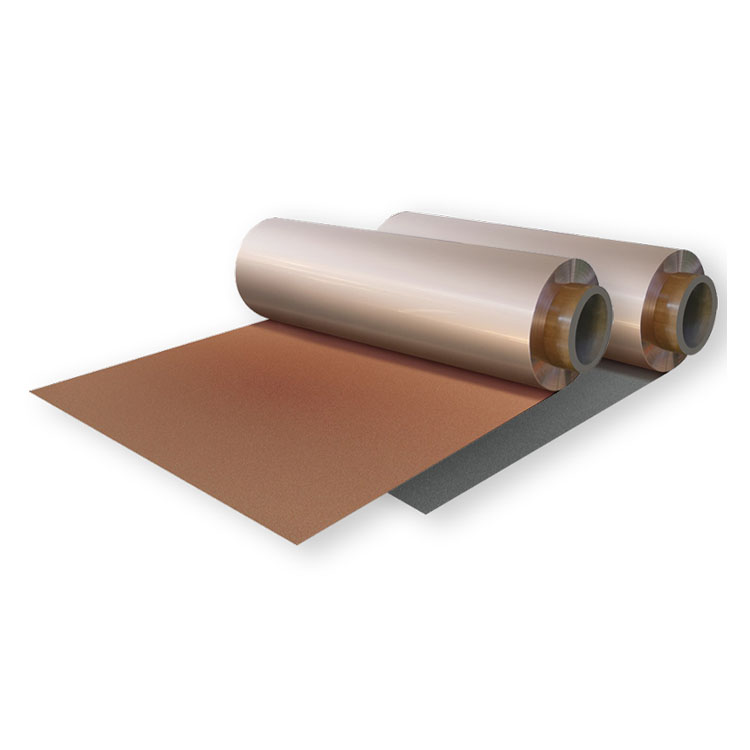

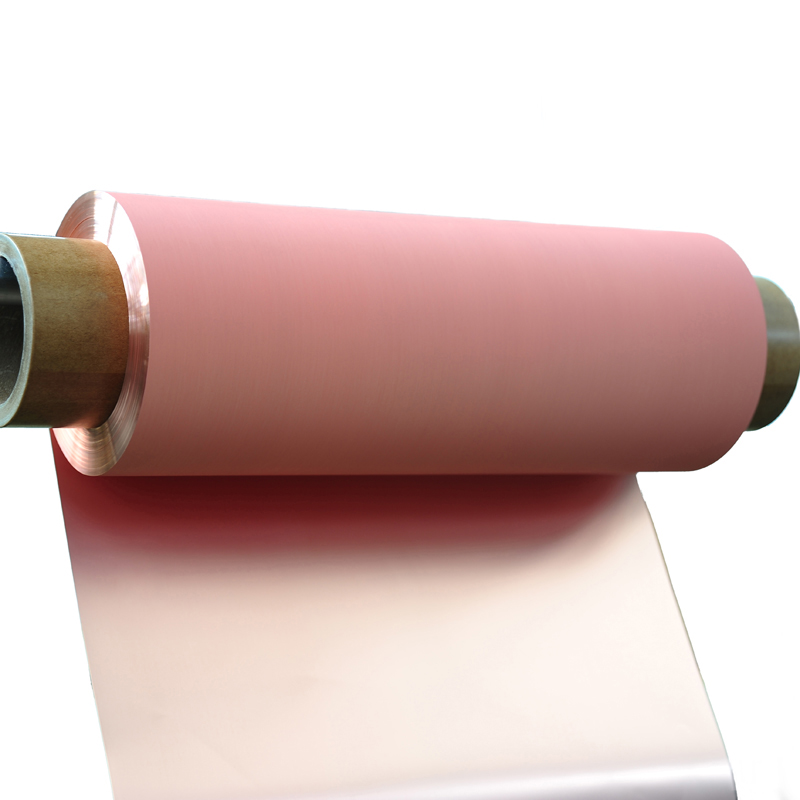

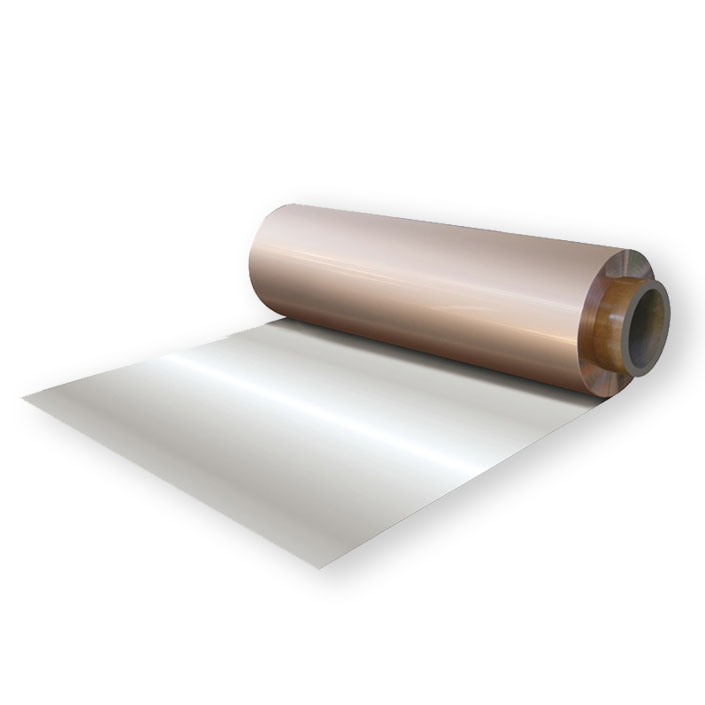

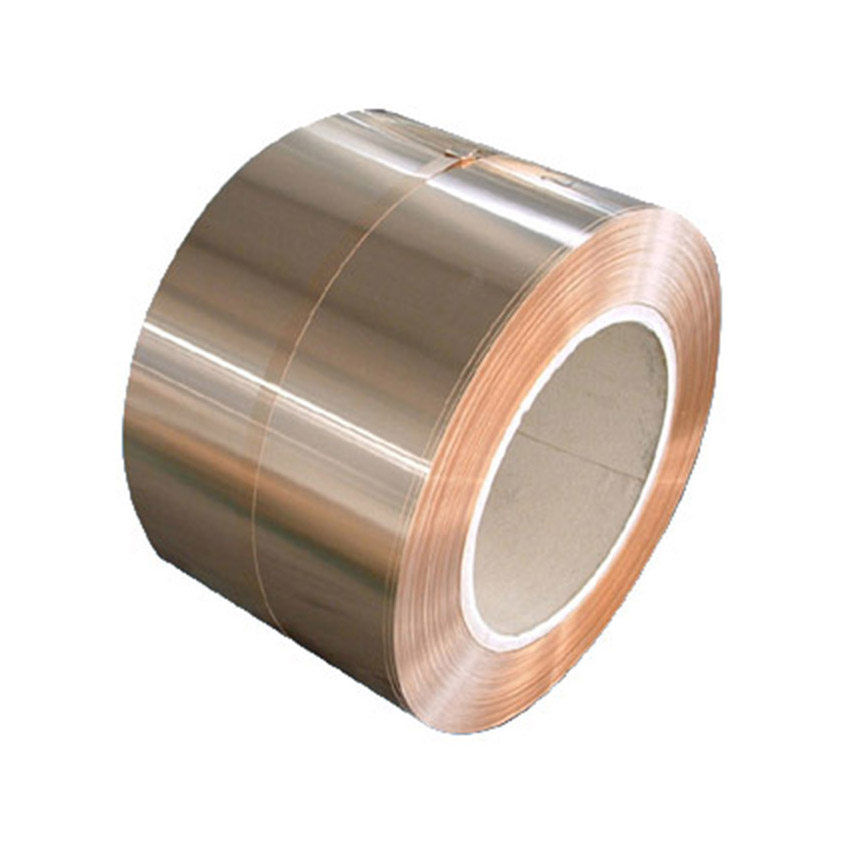

Product detail pictures:

Related Product Guide:

As for competitive selling prices, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we are the lowest around for Short Lead Time for Battery Copper Foil - Tin Plated Copper Foil – CIVEN , The product will supply to all over the world, such as: Myanmar, Nepal, India, If you are for any reason unsure which product to select, do not hesitate to contact us and we will be delighted to advise and assist you. This way we will be providing you with all the knowledge needed to make the best choice. Our company strictly follows "Survive by good quality, Develop by keeping good credit. " operation policy. Welcome all the clients old and new to visit our company and talk about the business. We are looking for more and more customers to create the glorious future.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!