Popular Design for Thermo Exchange Copper Foil - ED Copper Foils for FPC – CIVEN

Popular Design for Thermo Exchange Copper Foil - ED Copper Foils for FPC – CIVEN Detail:

Product Introduction

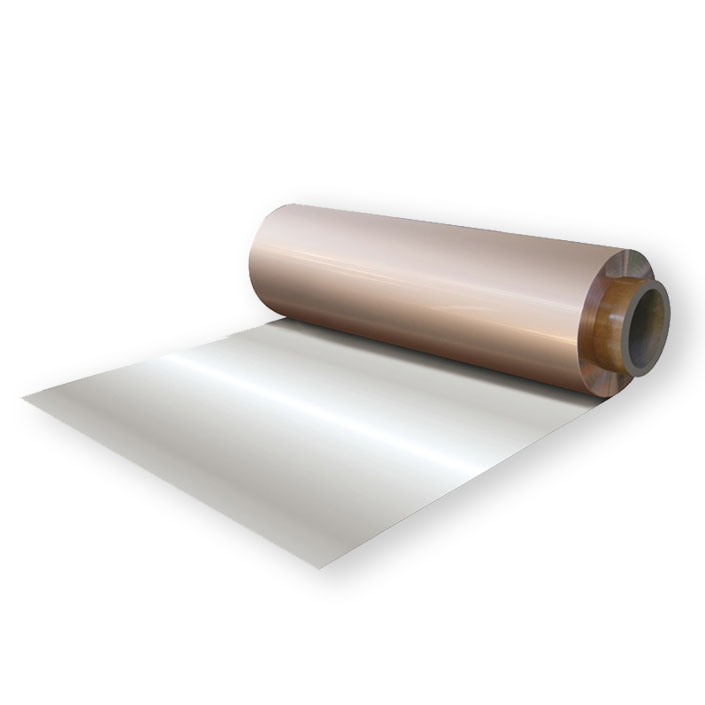

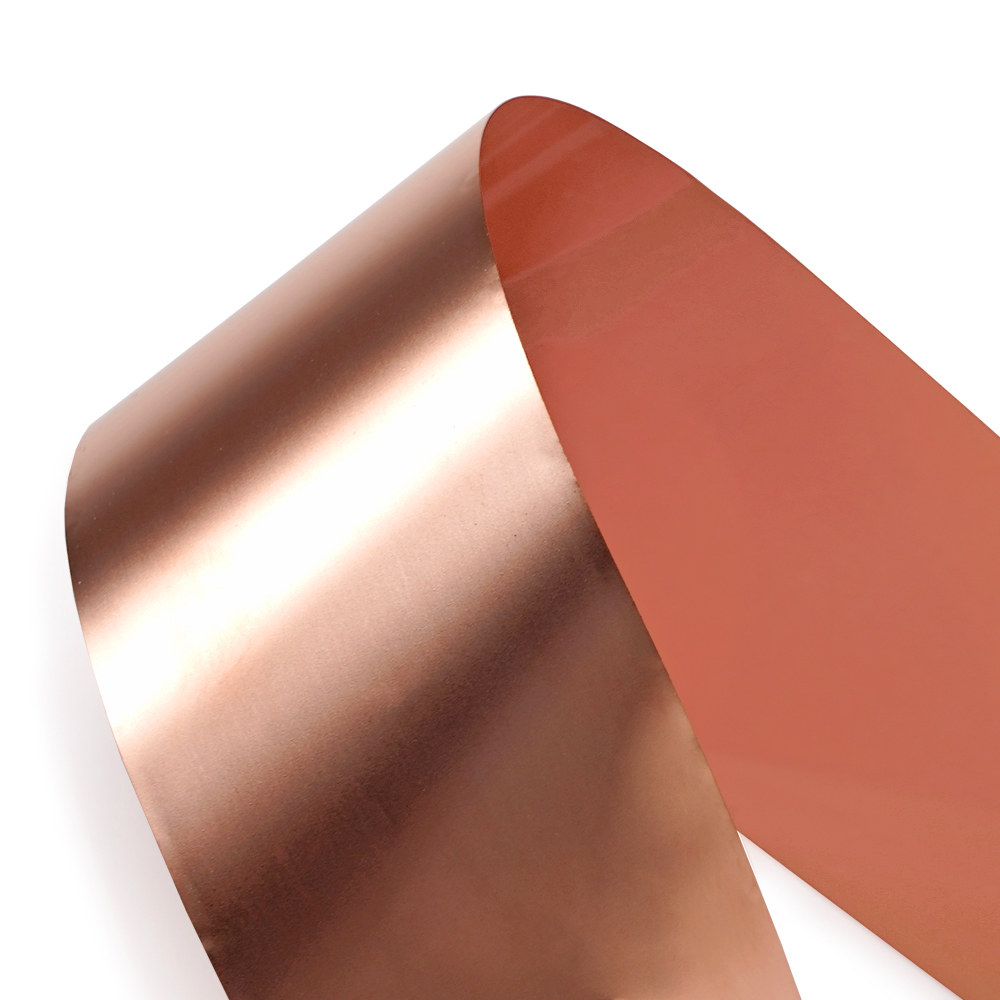

Electrolytic copper foil for FPC is specially developed and manufactured for the FPC industry (FCCL). This electrolytic copper foil has better ductility, lower roughness and better peel strength than other copper foils. At the same time, the surface finish and fineness of the copper foil is better and the folding resistance is also better than similar copper foil products. Since this copper foil is based on the electrolytic process, it does not contain grease, which makes it easier to be combined with TPI materials at high temperatures.

Dimension Range

Thickness: 9µm~35µm

Performances

The product surface is black or red, has lower surface roughness.

Applications

Flexible Copper Clad Laminate (FCCL), Fine Circuit FPC, LED coated crystal thin film.

Features

High density, high bending resistance and good etching performance.

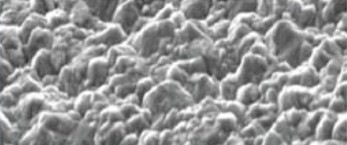

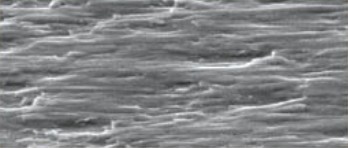

Microstructure

SEM(Before Surface Treatment)

SEM(Shiny Side after Treatment)

SEM(Rough Side after Treatment)

Table1- Performance (GB/T5230-2000、IPC-4562-2000)

|

Classification |

Unit |

9μm |

12μm |

18μm |

35μm |

|

|

Cu Content |

% |

≥99.8 |

||||

|

Area Weigth |

g/m2 |

80±3 |

107±3 |

153±5 |

283±7 |

|

|

Tensile Strength |

R.T.(23℃) |

Kg/mm2 |

≥28 |

|||

|

H.T.(180℃) |

≥15 |

≥15 |

≥15 |

≥18 |

||

|

Elongation |

R.T.(23℃) |

% |

≥5.0 |

≥5.0 |

≥6.0 |

≥10 |

|

H.T.(180℃) |

≥6.0 |

≥6.0 |

≥8.0 |

≥8.0 |

||

|

Roughness |

Shiny(Ra) |

μm |

≤0.43 |

|||

|

Matte(Rz) |

≤2.5 |

|||||

|

Peel Strength |

R.T.(23℃) |

Kg/cm |

≥0.77 |

≥0.8 |

≥0.8 |

≥0.8 |

|

Degraded rate of HCΦ(18%-1hr/25℃) |

% |

≤7.0 |

||||

|

Change of color(E-1.0hr/200℃) |

% |

Good |

||||

|

Solder Floating 290℃ |

Sec. |

≥20 |

||||

|

Appearance(Spot and copper powder) |

—- |

None |

||||

|

Pinhole |

EA |

Zero |

||||

|

Size Tolerance |

Width |

mm |

0~2mm |

|||

|

Length |

mm |

—- |

||||

|

Core |

Mm/inch |

Inside Diameter 79mm/3 inch |

||||

Note: 1. Copper foil oxidation resistance performance and surface density index can be negotiated.

2. The performance index is subject to our testing method.

3. The quality guarantee period is 90 days from the date of receipt.

Product detail pictures:

Related Product Guide:

Together with the "Client-Oriented" enterprise philosophy, a arduous good quality control technique, sophisticated producing equipment and a sturdy R&D staff, we generally offer superior quality merchandise, superb solutions and aggressive rates for Popular Design for Thermo Exchange Copper Foil - ED Copper Foils for FPC – CIVEN , The product will supply to all over the world, such as: Mecca, Brunei, Rome, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.