OEM/ODM Factory Cupronickel Foil - Copper Strip for Lead Frame – CIVEN

OEM/ODM Factory Cupronickel Foil - Copper Strip for Lead Frame – CIVEN Detail:

Product Introduction

The material for lead frame is always made from alloy of copper, Iron and phosphorus, or copper, nickel and silicon, which have the common alloy No. of C192(KFC),C194 and C7025.These alloys have high strength and performance.C194 and KFC are most representative for copper, iron and phosphorus alloy, they are the most common alloy materials.

C7025 is the alloy of copper and phosphorus, silicon. It has high thermal conductivity and high flexibility, and do not need heat treatment, also it’s easy for stamping. It has high strength, excellent thermal conductivity properties, and very suitable for lead frames, especially for assembly of high density integrated circuits.

Copper alloys for lead frames are roughly divided into copper iron system, copper nickel silicon system, copper chromium system, copper nickel tin system (jk-2 alloy), etc. ternary and quaternary copper alloys can achieve better performance and lower cost than traditional binary alloys. Copper iron alloys have the most brands and have better mechanical strength, stress relaxation resistance and low creep, It is a kind of good lead frame material. Due to the needs of lead frame fabrication and packaging applications, in addition to high strength and high thermal conductivity, the materials are also required to have good brazing performance, process performance, etching performance, oxide film bonding performance, etc. The materials are developing in the direction of high strength, high conductivity and low cost. A small amount of various elements are added to copper to improve the alloy strength (so that the lead frame is not easy to deform) and comprehensive properties without significantly reducing the conductivity. The materials with tensile strength above 600MPa and conductivity greater than 80% IACS are the research and development hotspot. The copper strip is required to be high surface, accurate plate shape, uniform performance, continuous thinning of strip thickness, gradual thinning from 0.25mm to o.15mm and 0.lmm, and ultra-thin and profiled of 0.07-0.qiao.

Main Technical Parameters

Chemical composition

|

Name |

Alloy No. |

Chemical Composition(%) |

|||||

|

Fe |

P |

Ni |

Si |

Mg |

Cu |

||

|

Copper-Iron-Phosphorus Alloy |

QFe0.1/C192/KFC |

0.05-0.15 |

0.015-0.04 |

— |

— |

— |

Rem |

|

QFe2.5/C194 |

2.1-2.6 |

0.015-0.15 |

— |

— |

— |

Rem |

|

|

Copper-Nickel-Silicon Alloy |

C7025 |

—– |

—– |

2.2-4.2 |

0.25-1.2 |

0.05-0.3 |

Rem |

Technical Parameters

|

Alloy No. |

Temper |

Mechanical properties |

||||

|

Tensile Strength |

Elongation |

Hardness |

Elctricity Conductivity |

Thermal Conductivity W/(m.K) |

||

|

C192/KFC/C19210 |

O |

260-340 |

≥30 |

<100 |

85 |

365 |

|

1/2H |

290-440 |

≥15 |

100-140 |

|||

|

H |

340-540 |

≥4 |

110-170 |

|||

|

C194/C19410 |

1/2H |

360-430 |

≥5 |

110-140 |

60 |

260 |

|

H |

420-490 |

≥2 |

120-150 |

|||

|

EH |

460-590 |

—- |

140-170 |

|||

|

SH |

≥550 |

—- |

≥160 |

|||

|

C7025 |

TM02 |

640-750 |

≥10 |

180-240 |

45 |

180 |

|

TM03 |

680-780 |

≥5 |

200-250 |

|||

|

TM04 |

770-840 |

≥1 |

230-275 |

|||

Note: Above figures based on the material thickness 0.1~3.0mm.

Typical Applications

● Lead frame for Integrated Circuits, Electrical connectors, Transistors, LED stents.

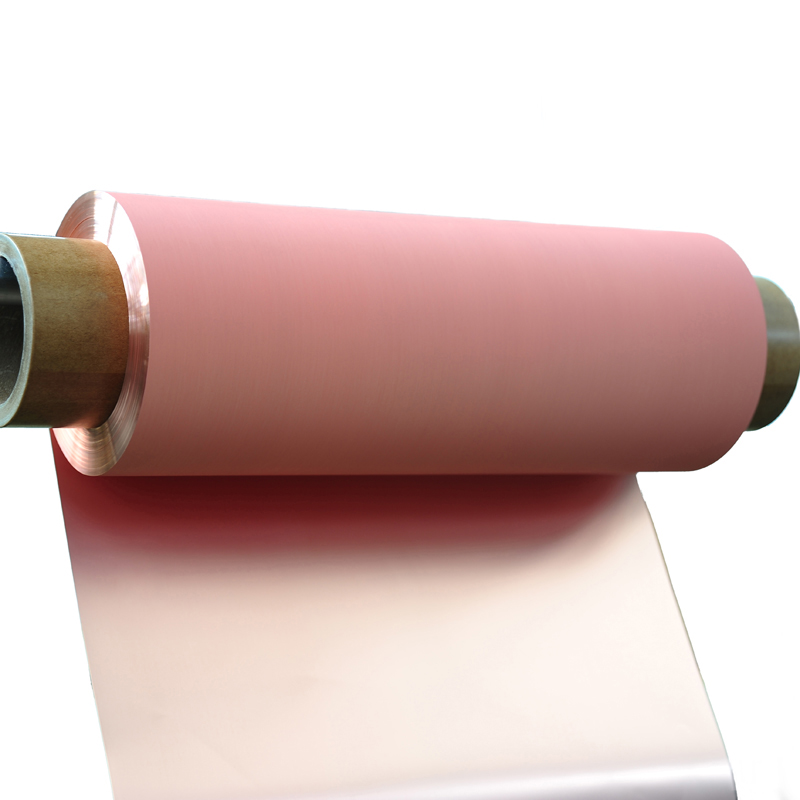

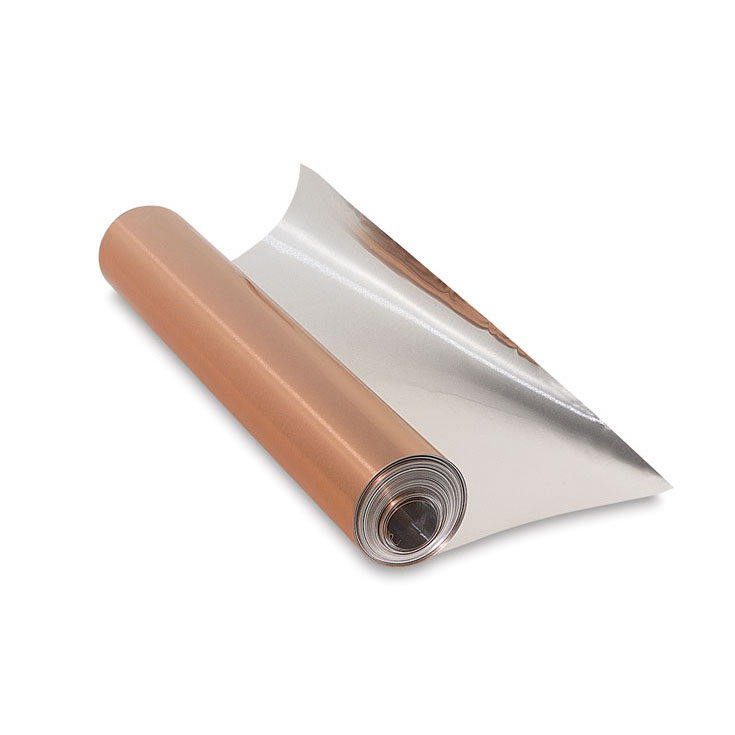

Product detail pictures:

Related Product Guide:

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for OEM/ODM Factory Cupronickel Foil - Copper Strip for Lead Frame – CIVEN , The product will supply to all over the world, such as: Thailand, Myanmar, Austria, We expect to provide products and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.