OEM Manufacturer Cu-Ni Foil - Shielded ED copper foils – CIVEN

OEM Manufacturer Cu-Ni Foil - Shielded ED copper foils – CIVEN Detail:

Product Introduction

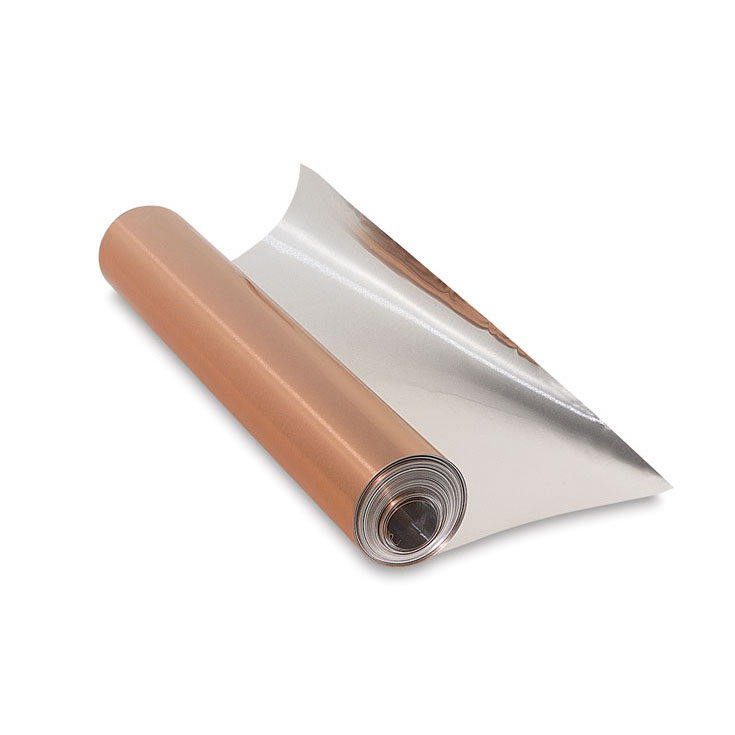

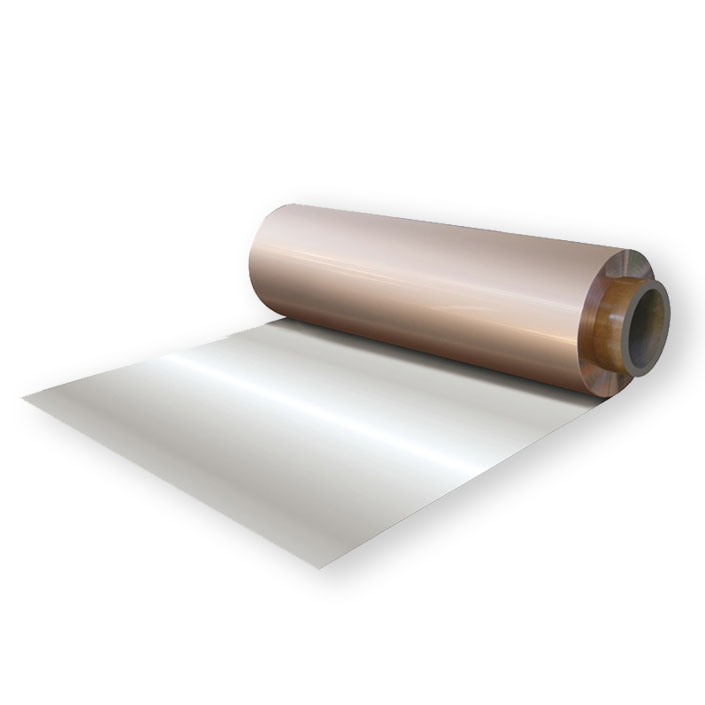

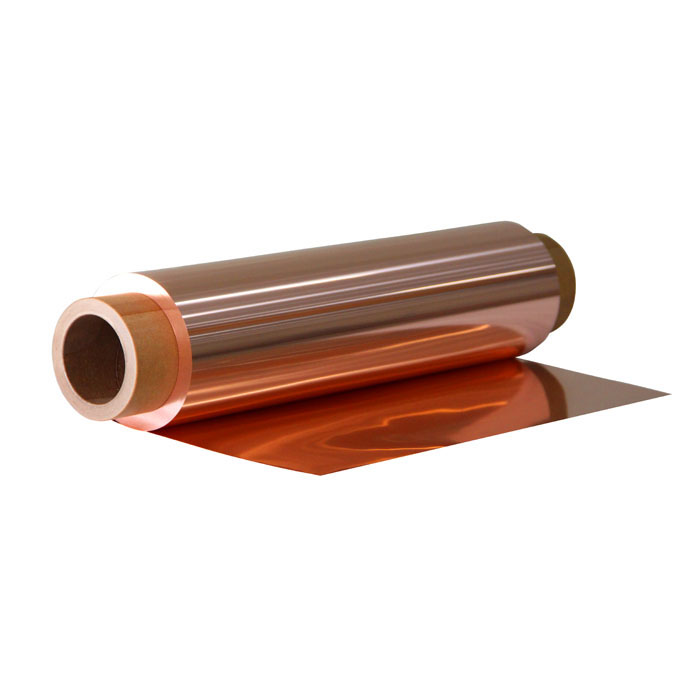

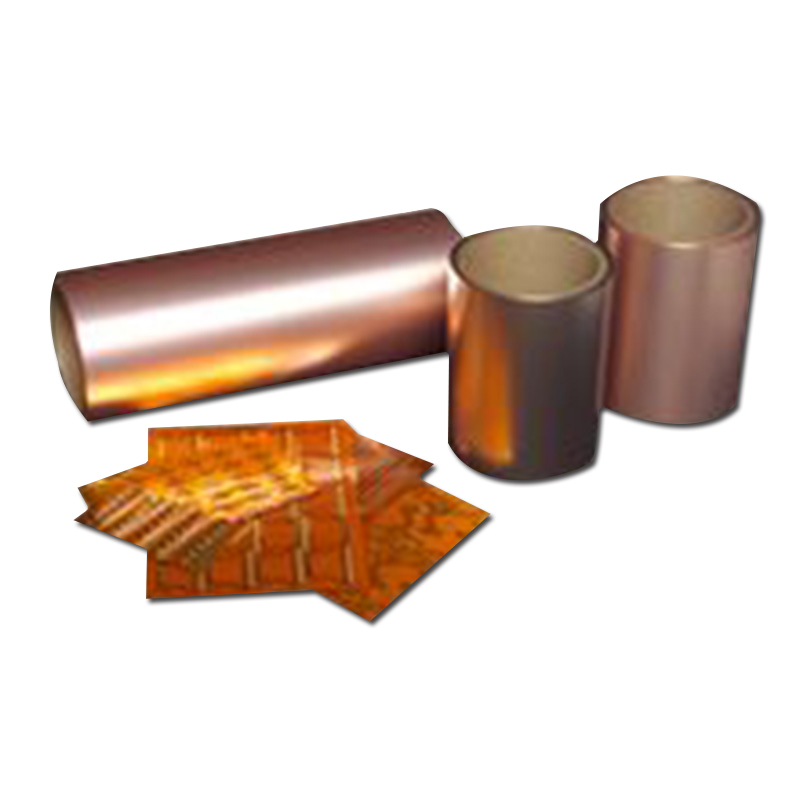

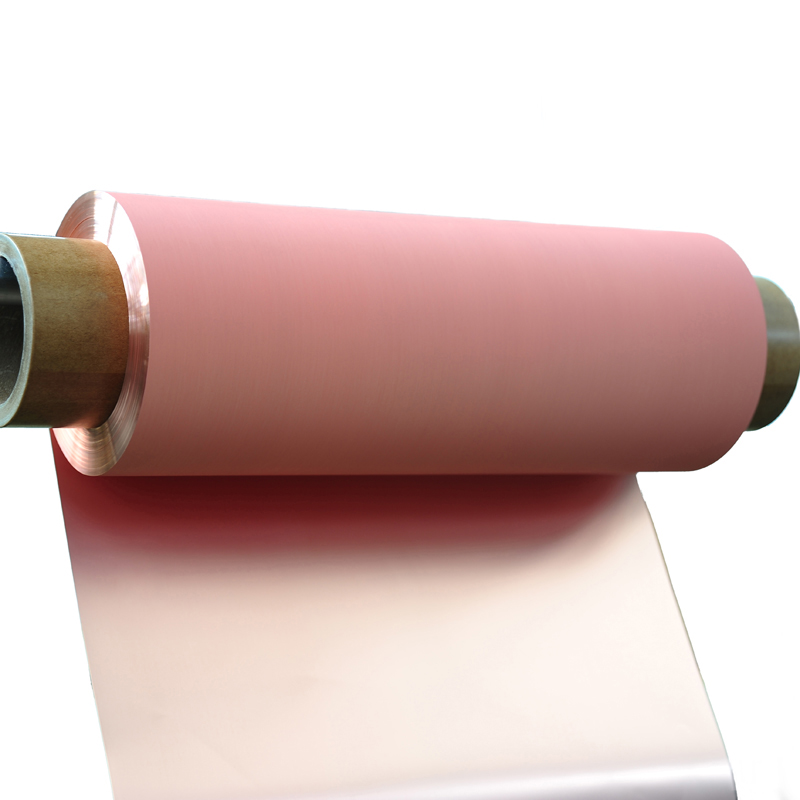

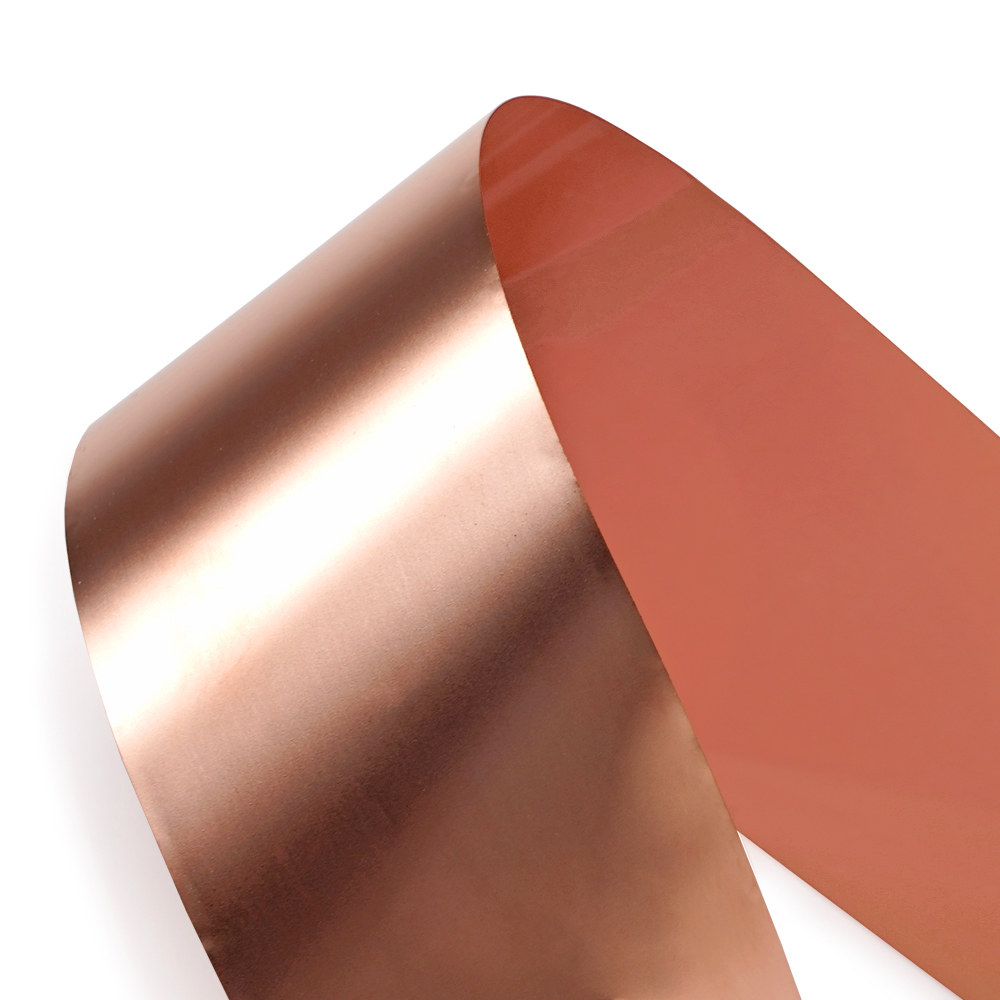

The electrolytic copper foil for shielding produced by CIVEN METAL can effectively shield electromagnetic signals and microwave interference because of the high purity of copper. The electrolytic production process makes the width of material wider than 1.2 meters(48 inches), which allows for flexible applications in a wide range of fields. The copper foil itself has a very flat shape and can be perfectly molded to other materials. The copper foil is also resistant to high temperature oxidation and corrosion, allowing it to be used in harsh environments or in products where material life is critical.

Specifications

CIVEN can provide 1/4oz-3oz (nominal thickness 9μm -105μm) shielding electrolytic copper foil with a maximum width of 1290mm, or various specifications of shielding electrolytic copper foil with a thickness of 9μm -105μm according to customer requirements with product quality meeting the requirements of IPC-4562 standard II and III.

Performance

It has good moisture resistance, chemical resistance, thermal conductivity and UV resistance, and is suitable for preventing interference with static electricity and electromagnetic waves.

Applications

Mainly used: transformers, cables, cell phones, computers, medical, aerospace, military and other electronic products shielding.

Performance(GB/T5230-2000、IPC-4562-2000)

|

Classification |

Unit |

9μm |

12μm |

18μm |

35μm |

50μm |

70μm |

105μm |

|

|

Cu Content |

% |

≥99.8 |

|||||||

|

Area Weigth |

g/m2 |

80±3 |

107±3 |

153±5 |

283±7 |

440±8 |

585±10 |

875±15 |

|

|

Tensile Strength |

R.T.(23℃) |

Kg/mm2 |

≥28 |

||||||

|

H.T.(180℃) |

≥15 |

≥18 |

≥20 |

||||||

|

Elongation |

R.T.(23℃) |

% |

≥5.0 |

≥6.0 |

≥10 |

||||

|

H.T.(180℃) |

≥6.0 |

≥8.0 |

|||||||

|

Roughness |

Shiny(Ra) |

μm |

≤0.43 |

||||||

|

Matte(Rz) |

≤3.5 |

||||||||

|

Peel Strength |

R.T.(23℃) |

Kg/cm |

≥0.77 |

≥0.8 |

≥0.9 |

≥1.0 |

≥1.0 |

≥1.5 |

≥2.0 |

|

Degraded rate of HCΦ(18%-1hr/25℃) |

% |

≤7.0 |

|||||||

|

Change of color(E-1.0hr/200℃) |

% |

Good |

|||||||

|

Solder Floating 290℃ |

Sec. |

≥20 |

|||||||

|

Appearance(Spot and copper powder) |

—- |

None |

|||||||

|

Pinhole |

EA |

Zero |

|||||||

|

Size Tolerance |

Width |

0~2mm |

0~2mm |

||||||

|

Length |

—- |

—- |

|||||||

|

Core |

Mm/inch |

Inside Diameter 76mm/3 inch |

|||||||

Note: 1. The Rz value of copper foil gross surface is the test stable value, not a guaranteed value.

2. Peel strength is the standard FR-4 board test value (5 sheets of 7628PP).

3. Quality assurance period is 90 days from the date of receipt.

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, more united and more professional team! To reach a mutual benefit of our customers, suppliers, the society and ourselves for OEM Manufacturer Cu-Ni Foil - Shielded ED copper foils – CIVEN , The product will supply to all over the world, such as: Belgium, Porto, UAE, Our mission is "Provide Goods with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.