OEM Manufacturer Cu-Ni Foil - PriceList for China Pure Copper Foil Specialized for Lithium Battery – CIVEN

OEM Manufacturer Cu-Ni Foil - PriceList for China Pure Copper Foil Specialized for Lithium Battery – CIVEN Detail:

With our loaded working experience and thoughtful products and services, we’ve got been acknowledged as a reputable supplier for most international buyers for PriceList for China Pure Copper Foil Specialized for Lithium Battery, We imagine we are going to become a leader in developing and producing high-quality products and solutions in both Chinese and international markets. We hope to cooperate with more friends for mutual advantages.

With our loaded working experience and thoughtful products and services, we’ve got been acknowledged as a reputable supplier for most international buyers for China Copper Foil, Copper Sheet, We also have good cooperation relationships with many good manufacturers so that we can give almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Product Introduction

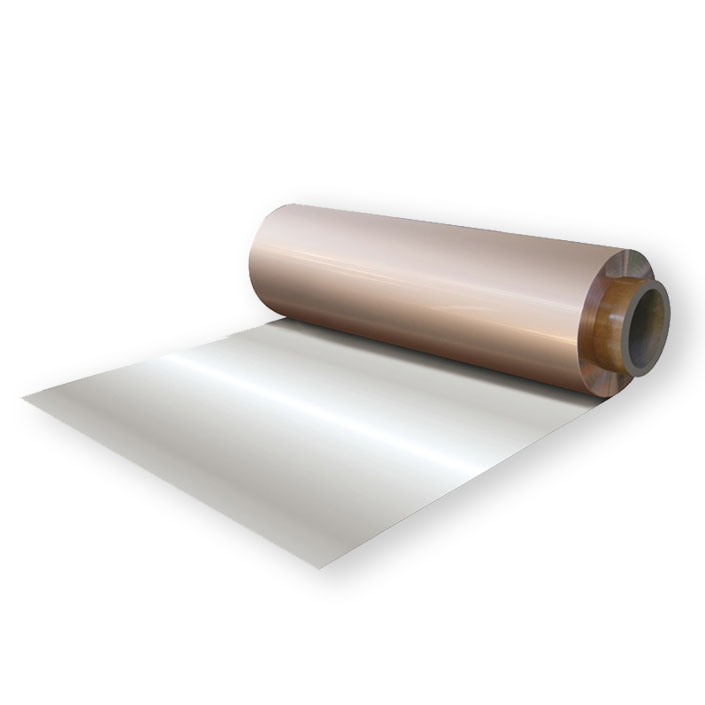

Reverse treated electrolytic copper foil (RTF) is a copper foil that has been roughened to varying degrees on both sides. This strengthens the peel strength of both sides of the copper foil, making it easier to use as an intermediate layer for bonding to other materials. Moreover, the different levels of treatment on both sides of the copper foil make it easier to etch the thinner side of the roughened layer. In the process of making a printed circuit board (PCB) panel, the treated side of the copper is applied to the dielectric material. The treated drum side is rougher than the other side, which constitutes a greater adhesion to the dielectric. This is the main advantage over standard electrolytic copper. The matte side does not require any mechanical or chemical treatment prior to the application of photoresist. It is already rough enough to have good laminating resist adhesion.

Specifications

CIVEN can supply RTF electrolytic copper foil with nominal thickness of 12 to 35µm up to 1295mm width.

Performance

The high temperature elongation reversed treated electrolytic copper foil is subjected to a precise plating process to control the size of the copper tumors and distribute them evenly. The reversed treated bright surface of the copper foil can significantly reduce the roughness of the copper foil pressed together and provide sufficient peel strength of the copper foil. (See Table 1)

Applications

Can be used for high-frequency products and inner laminates, such as 5G base stations and automotive radar and other equipment.

Advantages

Good bonding strength, direct multi-layer lamination, and good etching performance. It also reduces the potential for short circuit and shortens the process cycle time.

Table 1. Performance

|

Classification |

Unit |

1/3OZ (12μm) |

1/2OZ (18μm) |

1OZ (35μm) |

|

|

Cu Content |

% |

min. 99.8 |

|||

|

Area Weigth |

g/m2 |

107±3 |

153±5 |

283±5 |

|

|

Tensile Strength |

R.T.(25℃) |

Kg/mm2 |

min. 28.0 |

||

|

H.T.(180℃) |

min. 15.0 |

min. 15.0 |

min. 18.0 |

||

|

Elongation |

R.T.(25℃) |

% |

min. 5.0 |

min. 6.0 |

min. 8.0 |

|

H.T.(180℃) |

min. 6.0 |

||||

|

Roughness |

Shiny(Ra) |

μm |

max. 0.6/4.0 |

max. 0.7/5.0 |

max. 0.8/6.0 |

|

Matte(Rz) |

max. 0.6/4.0 |

max. 0.7/5.0 |

max. 0.8/6.0 |

||

|

Peel Strength |

R.T.(23℃) |

Kg/cm |

min. 1.1 |

min. 1.2 |

min. 1.5 |

|

Degraded rate of HCΦ(18%-1hr/25℃) |

% |

max. 5.0 |

|||

|

Change of color(E-1.0hr/190℃) |

% |

None |

|||

|

Solder Floating 290℃ |

Sec. |

max. 20 |

|||

|

Pinhole |

EA |

Zero |

|||

|

Preperg |

—- |

FR-4 |

|||

Note: 1. The Rz value of copper foil gross surface is the test stable value, not a guaranteed value.

2. Peel strength is the standard FR-4 board test value (5 sheets of 7628PP).

3. Quality assurance period is 90 days from the date of receipt.

With our loaded working experience and thoughtful products and services, we’ve got been acknowledged as a reputable supplier for most international buyers for PriceList for China Pure Copper Foil Specialized for Lithium Battery, We imagine we are going to become a leader in developing and producing high-quality products and solutions in both Chinese and international markets. We hope to cooperate with more friends for mutual advantages.

PriceList for China Copper Foil, Copper Sheet, We also have good cooperation relationships with many good manufacturers so that we can give almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Product detail pictures:

Related Product Guide:

Our company has been focusing on brand strategy. Customers' satisfaction is our best advertising. We also supply OEM service for OEM Manufacturer Cu-Ni Foil - PriceList for China Pure Copper Foil Specialized for Lithium Battery – CIVEN , The product will supply to all over the world, such as: Florida, Hanover, Turkmenistan, We expect to provide products and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!