OEM Manufacturer Copper Foil Adhesive Tape - Treated RA Copper Foil – CIVEN

OEM Manufacturer Copper Foil Adhesive Tape - Treated RA Copper Foil – CIVEN Detail:

Product Introduction

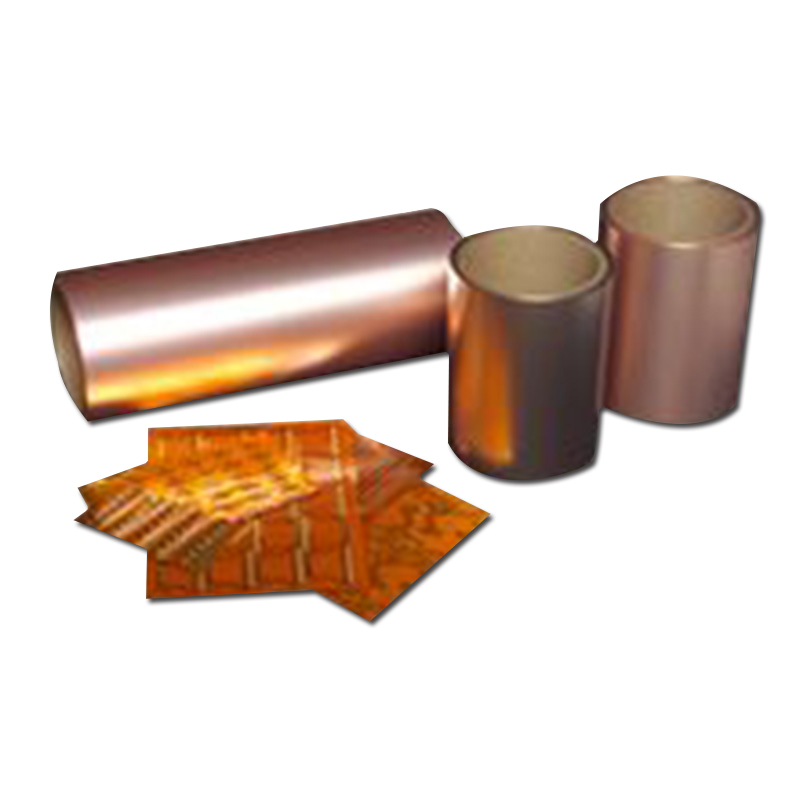

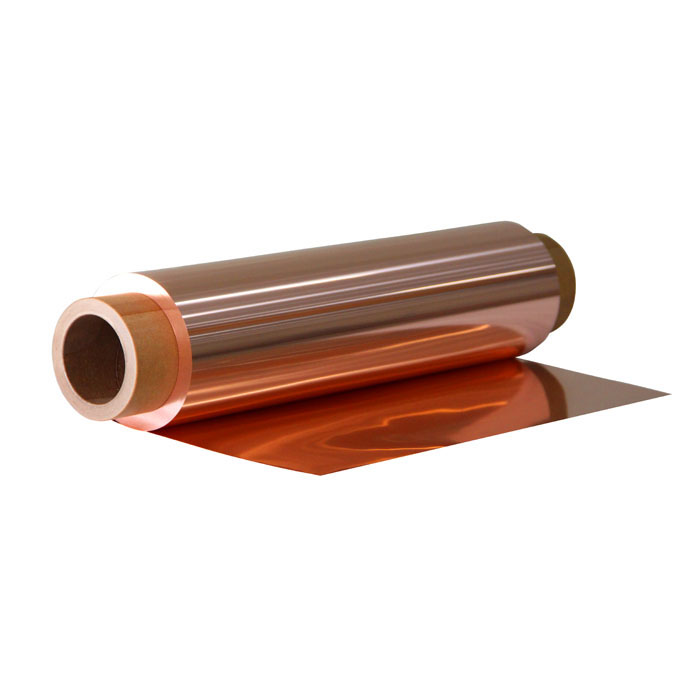

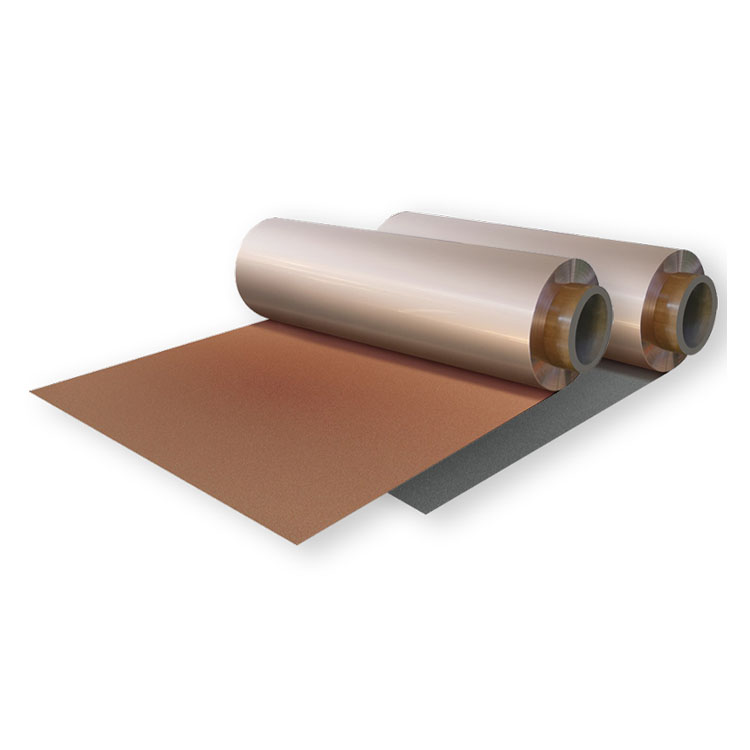

Treated RA copper foil is a single side roughened high precision copper foil in order to increase its peel strength. The roughened surface of copper foil likes a frosted texture, which makes it easier to laminate with other materials and less likely to peel off. There are two mainstream treatment methods: one is called reddening treatment, where the main ingredient is copper powder and the surface color is red after treatment; the other is blackening treatment, where the main ingredient is cobalt and nickel powder and the surface color is black after treatment. The treated RA copper foil produced by CIVEN METAL has the characteristics of stable thickness tolerance, no powder off out the roughened surface and good uniformity of copper buds. At the same time, CIVEN METAL also applies high-temperature anti-oxidation treatment on the shiny side of the treated RA copper foil to prevent the material from color changing at high temperatures during client processing. This type of copper foil is manufactured and packaged in a dust free room to ensure the cleanliness of the material, making it more suitable for high-end electronic material processing. CIVEN METAL can also customize the production according to customer requirements to better meet the their demanding on high-end materials.

Dimension Range

● Thickness range: 12~70 µm (1/3 to 2 OZ)

● Width Range: 150 ~ 600 mm (5.9 to 23.6 inch)

Performances

● High flexibility and extensibility

● Even and smooth surface

● Good fatigue resistance

● Strong antioxidant properties

● Good mechanical properties

Applications

Flexible Copper Clad Laminate(FCCL), Fine Circuit FPC, LED coated crystal thin film.

Features

The material has higher extensibility, and has a high bending resistance and no crack.

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of OEM Manufacturer Copper Foil Adhesive Tape - Treated RA Copper Foil – CIVEN , The product will supply to all over the world, such as: Slovakia, Porto, Afghanistan, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!