Copper foil for PCB

Due to the increased use of electronic devices, the demand for these devices has constantly been high in the market. These devices currently surround us as we greatly depend on them for different purposes. For this reason, I bet you have come across an electronic device or usually use them at home. If you use these devices, you may wonder how the electronic device components are wired, how it works, and how the device can be connected to other stuff. The electronic devices we use at home are made of materials that do not conduct electricity. They have pathways etched by conductive copper material on their surface, allowing the signal to flow within the device when it is under operation.

Therefore, the technology of PCB is based on understanding the working of electrical devices. The PCB is always majorly used in electronic devices designed for media. However, in the modern generation, they are implemented in all electronic devices. For this reason, no electronic device can operate without a PCB. This blog focuses on the copper foil for PCB, and the role played by the copper foil in the circuit board industry.

The Printed Circuit Board (PCB) Technology

The PCBs are the pathways that are electrically conductive such as traces and tracks, which are laminated with a copper foil. This makes them connect and supports other electronic components connected mechanically to the device. For this reason, the main function of these PCBs in electronic devices is to offer support to the pathways. In most cases, materials such as fiberglass and plastics easily hold the copper foil in the circuit. The copper foil in PCB is usually laminated with a non-conductive substrate. In the PCB, the copper foil plays a crucial role in allowing the flow of electricity between various components of the device, thereby supporting their communication.

Soldiers are always connecting effectively between the PCB surface and the electronic devices. These solders are made using metal that makes them a strong adhesive; hence, they are reliable in offering mechanical support to the components. The PCB pathway is usually composted with many layers of different materials such as silkscreen and metals laminated with a substrate to make them a PCB.

The role of copper foil in the circuit board industry

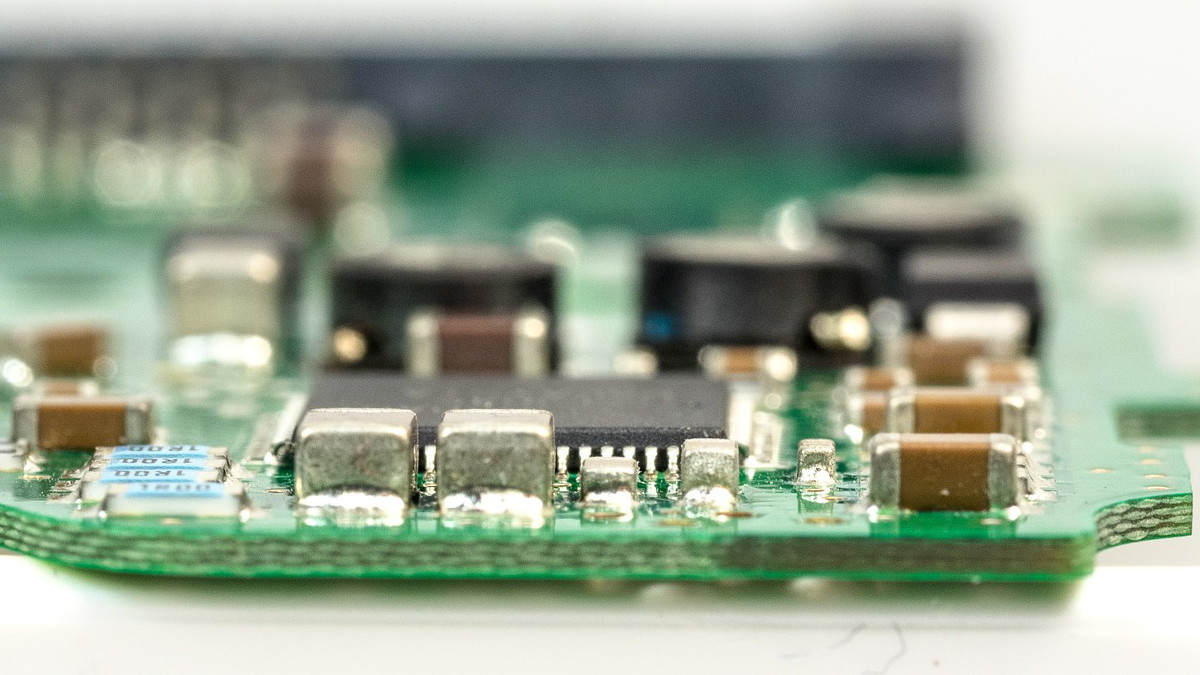

New technology trending today means no electronic device can function without a PCB. The PCB, on the other hand, rely on more on copper than the other components. This is because copper helps create traces that join all the components in the PCB to allow the flow of charge within the device. The traces can be described as the blood vessels in the skeleton of the PCB. Hence the PCB can not operate when the traces are missing. When the PCB fails to work, the electronic device will lose its concept, making it useless. Therefore, copper is the main conductivity component of the PCB. The copper foil in the PCB ensures a constant flow of signals without interruption.

The copper material is always known to have a high conductivity than other materials due to the free electrons present in its shell. The electrons are free to move without resistance to any atom making copper able to carry moving electric charges efficiently without any loss or interference in the signals. The copper, which makes a perfect negative electrolyte, is always used in PCBs as the first layer. Because copper is less affected by surface oxygen, it can be used by several kinds of substrates, insulating layers, and metals. When used with these substrates, it forms different patterns in the circuit, especially after etching. This is always made possible due to the ability of copper to make the perfect bond with the insulating layers used to make the PCB.

There are usually six layers of the PCB that are fabricated, out of which four layers are in the PCB. The other two layers are usually added to the inner panel. For this reason, the two layers are for internal use, there are also two for external use, and finally, the remaining two out of the total six layers are to enhance panels inside the PCB.

Conclusion

Copper foil is a significant component of the PCB that allows the flow of electric charges without interruption. It has high conductivity and perfectly forms a strong bond with different insulating materials used in the PCB circuit board. For this reason, a PCB relies on copper foil to work as it makes the connection of the PCB skeleton effective.

Post time: Jul-14-2022