News

-

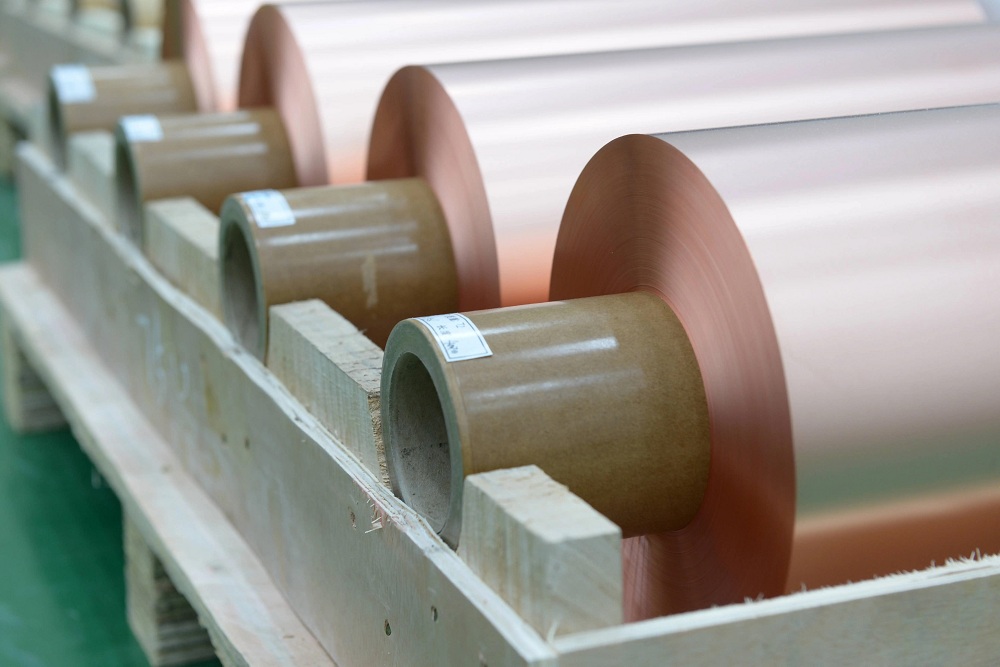

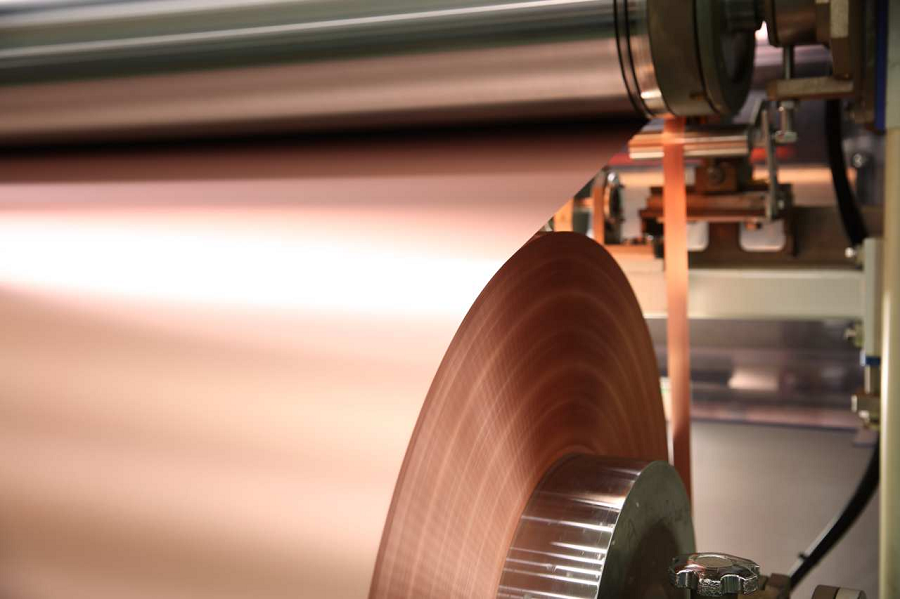

Application of Copper Foil in Power Battery Civen Metal

Introduction In 2021 China battery companies increased the introduction of thinner copper foil, and many companies have used their advantage by processing copper raw materials for battery production. To improve the energy density of batteries, companies are speeding up the production of thin and ...Read more -

Electrolytic Copper Foil’s Usage in Flexible Printed Circuits

Flexible printed circuit boards are a bendable type of circuit board manufactured for several reasons. Its benefits over traditional circuit boards include decreasing assembly errors, being more resilient in harsh environments, and being capable of handling more complex electronic configurations....Read more -

The Basics of Copper Foil in Lithium Ion Batteries

One of the most essential metals on the planet is copper. Without it, we are unable to do the things we take for granted such as turning on lights or watching TV. Copper are the arteries that make computers function. We wouldn’t be able to travel in cars without copper. Telecommunications w...Read more -

Copper Foil For Shielding-The Shielding Function Of Copper Foil For High-End Electronic Products

Wondering why Copper foil is the best shielding material? Electromagnetic and radio-frequency interference (EMI/RFI) is a major issue for shielded cable assemblies used in data transmission. The smallest disturbance could result in device failure, a reduction in signal quality, data loss, ...Read more -

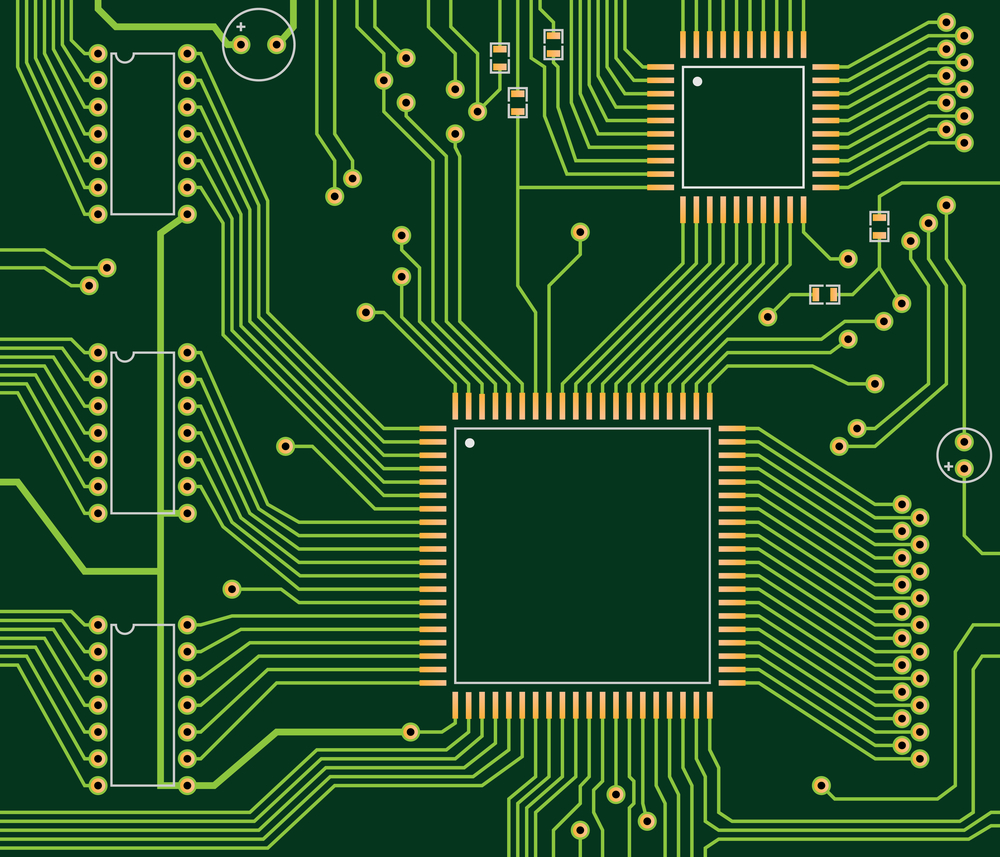

The Role of Copper Foil in the Circuit Board Industry

Copper foil for PCB Due to the increased use of electronic devices, the demand for these devices has constantly been high in the market. These devices currently surround us as we greatly depend on them for different purposes. For this reason, I bet you have come across an electronic device or us...Read more -

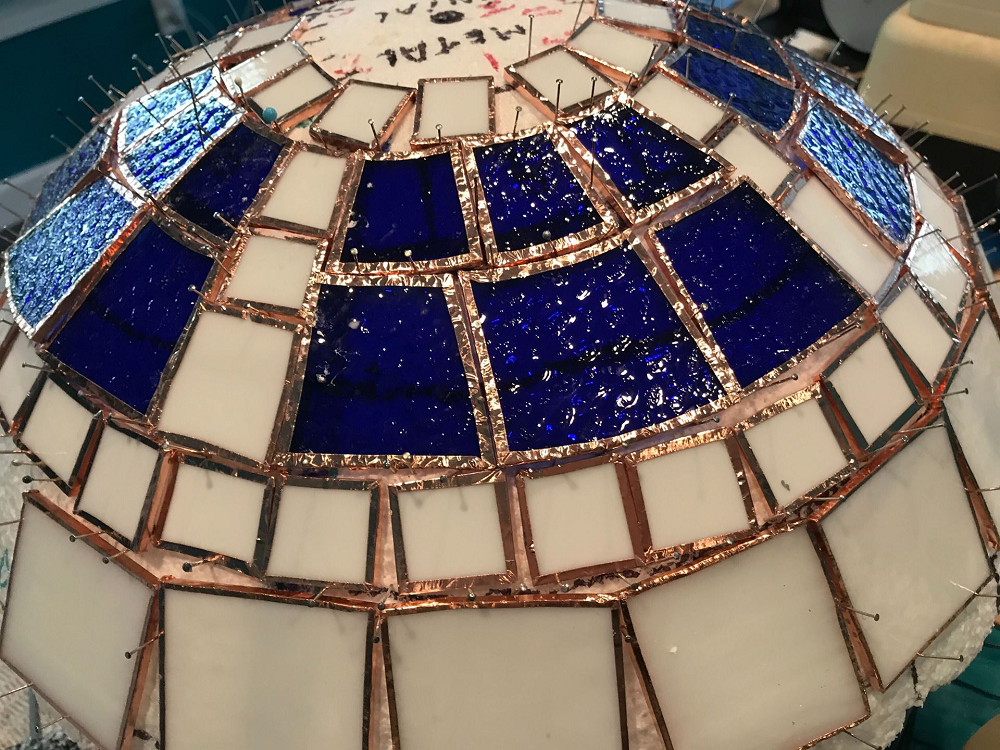

Choosing the Right Copper Foil for Discolored Glass

Creating art for discolored glass can be tricky, especially for newbies. The choice of the best copper foil is dictated by several factors like the size and thickness of the foil. You first don’t want to acquire a copper foil that doesn’t suit the project’s needs. Tips for selec...Read more -

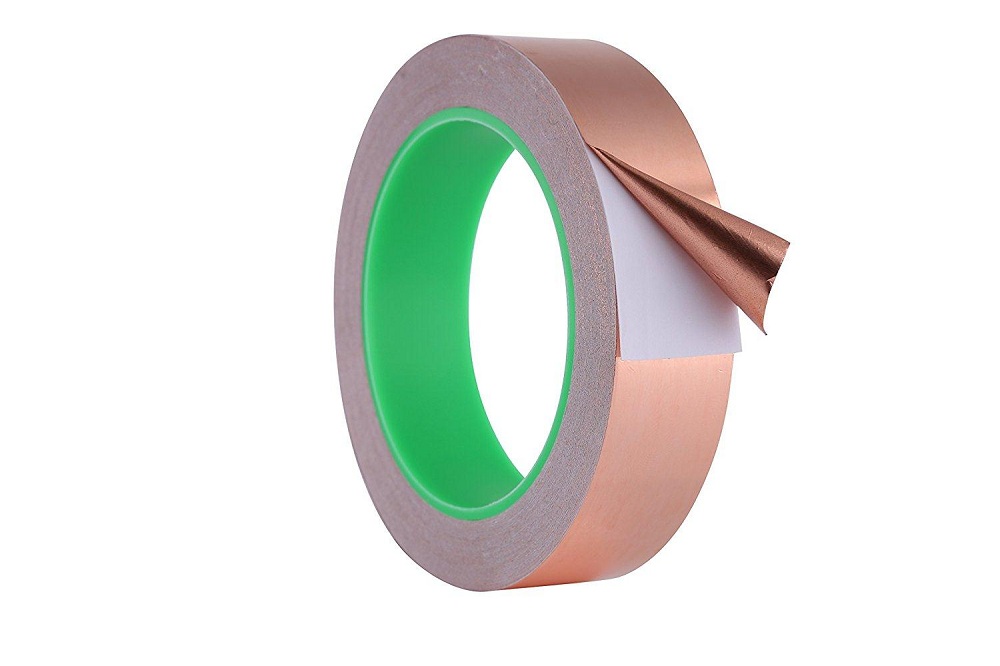

What you need to know about foil tapes?

Foil adhesive tapes are an extremely versatile and durable solution for rugged and harsh applications. Reliable adhesion, good thermal/electrical conductivity, and resistances to chemicals, humidity, and UV radiation make foil tape one of the most popular options for military, aerospace, and indu...Read more -

Types of PCB Copper Foil for High-Frequency Design

The PCB materials industry has spent significant amounts of time developing materials that provide lowest possible signal loss. For high speed and high frequency designs, losses will limit signal propagation distance and distort signals, and it will create an impedance deviation that can be seen ...Read more -

What is Copper Foil Used for PCB Manufacturing Process?

Copper foil has low rate of surface oxygen and can be attached with a variety of different substrates, such as metal, insulating materials. And copper foil is mainly applied in electromagnetic shielding and antistatic. To place the conductive copper foil on the substrate surface and combined with...Read more -

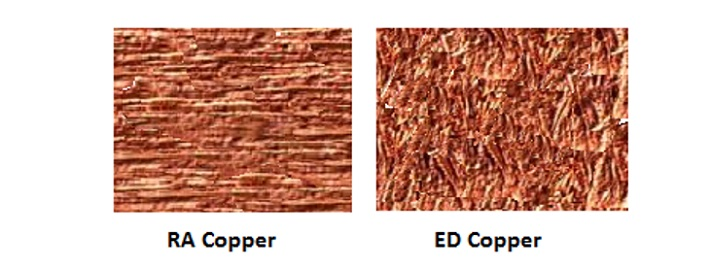

The Difference between RA Copper and ED Copper

We are often asked about flexibility. Of course, why else would you require a “flex” board? “Will the flex board crack if use ED copper on it?’’ Within this article we would like to investigate two different materials (ED-Electrodeposited and RA-rolled-annealed) and observe their impact on circui...Read more -

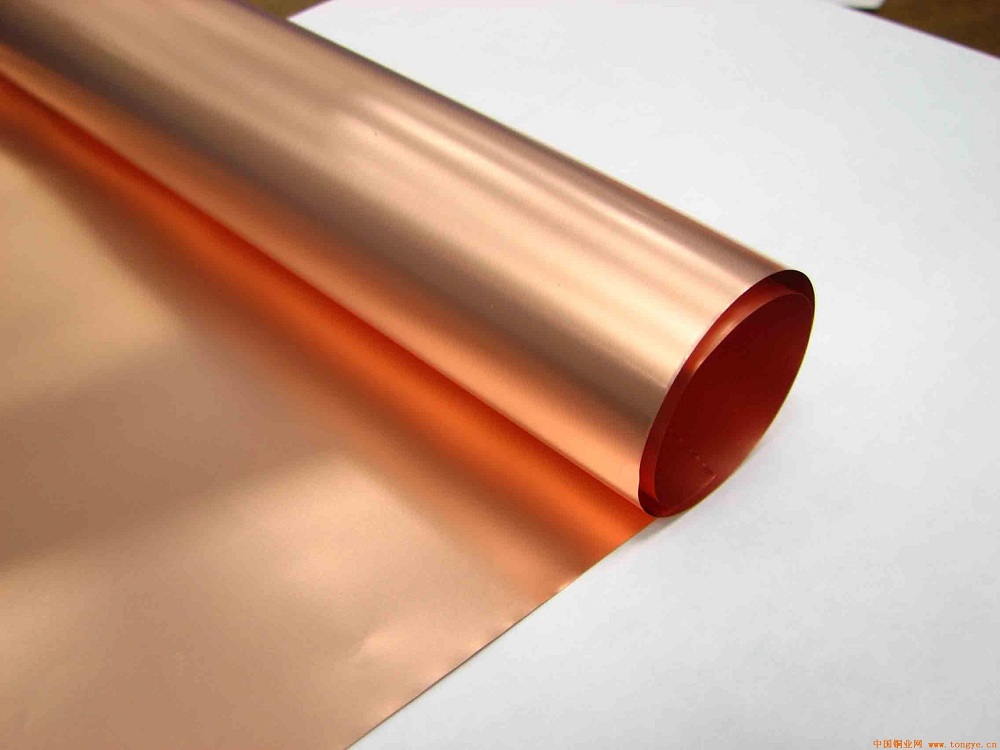

Copper Foil Used in Printed Circuit Board

Copper foil, a kind of negative electrolytic material, is deposited on base layer of PCB to form continuous metal foil and it is also named as the conductor of PCB. It is easily bonded to the insulating layer and able to be printed with a protective layer and form circuit pattern after etching. ...Read more -

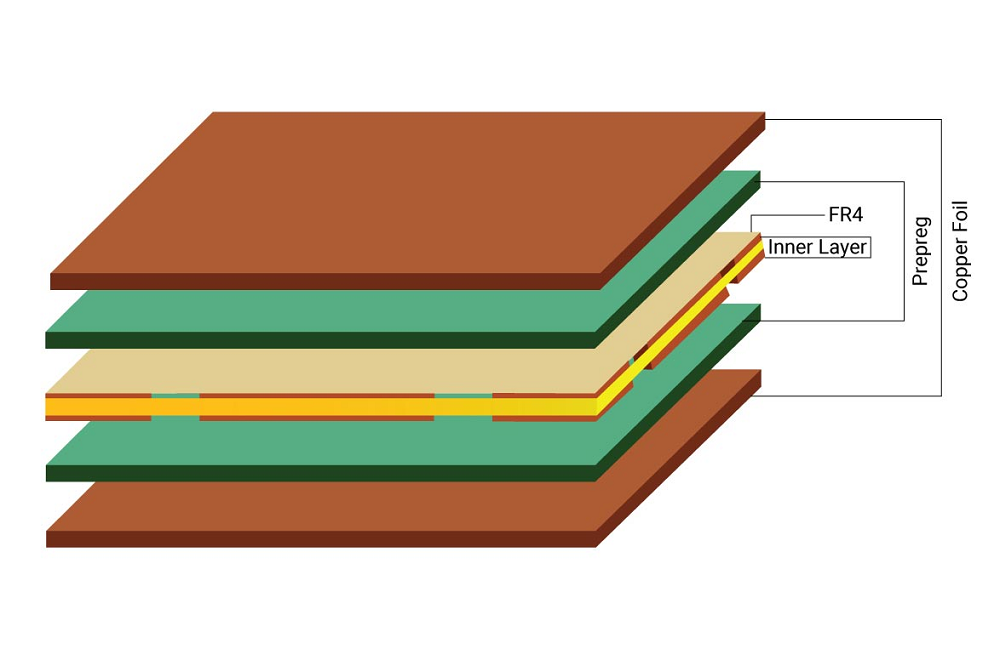

Why is Copper Foil used in PCB Manufacturing?

Printed circuit boards are necessary components of most electrical devices. Today’s PCBs have several layers to them: the substrate, traces, solder mask, and silkscreen. One of the most important materials on a PCB is copper, and there are several reasons why copper is used instead of other alloy...Read more