News

-

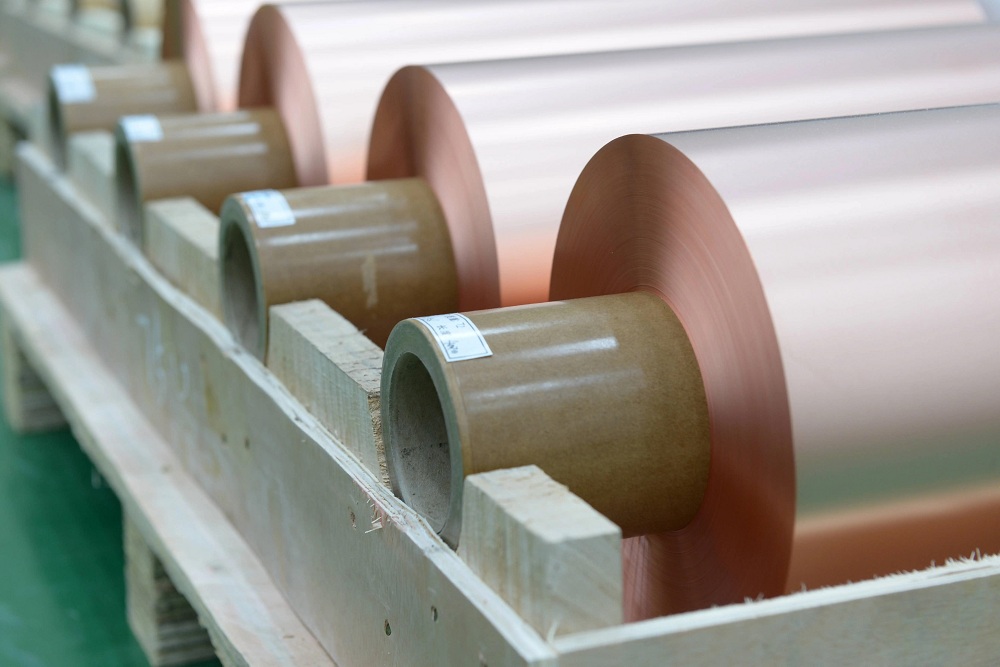

Application Of Copper Foil In Flexible Circuit Board

Application Of Copper Foil In Flexible Circuit Board Flexible printed circuit boards (FPCBs) have been widely adopted in the electronics industry because of their thinness, flexibility, and lightweight characteristics. A flexible copper clad laminate (FCCL) is an essential material in the product...Read more -

The Application of Copper Foil in Plate Heat Exchangers

The application of copper foil in plate heat exchangers has become a popular choice mainly due to the excellent properties of high thermal conductivity and corrosion resistance, which are essential for plate heat exchangers. Plate heat exchangers are a commonly used heat exchange device in indust...Read more -

ED Copper Foil in Our Daily Life

Copper is one of the most versatile metals in the world. Its unique properties make it suitable for a wide range of applications, including electrical conductivity. Copper is used extensively in electrical and electronics industries, and copper foils are essential components for manufacturing pri...Read more -

Comments from ChatGPT on CIVEN METAL

Hi ChatGPT!Tell me more about CIVEN METAL Civen Metal is a Chinese company that specializes in the production and sale ofvarious metal products, including copper foils. The company has been in the metalindustry for many years and has a reputation for providing high-quality products andservices t...Read more -

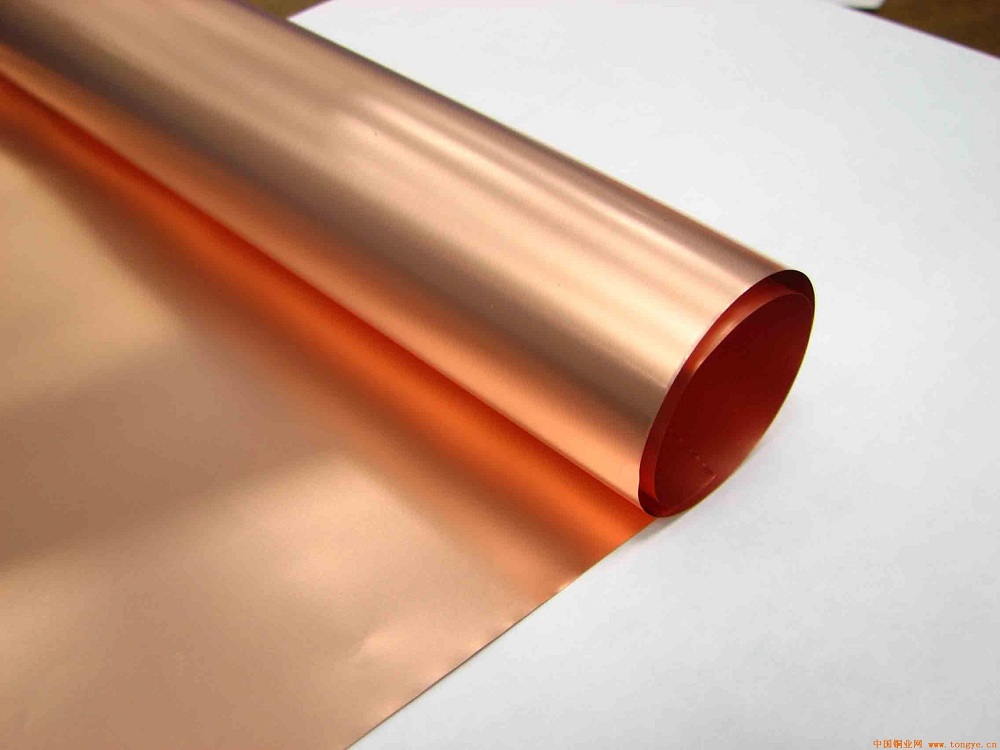

Application And Development Of Copper Foils For Electronic Field Civen Metal

The use of copper foil in electronic products has become increasingly prevalent in recent years due to its unique properties and versatility. Copper foil, which is a thin sheet of copper that has been rolled or pressed into a desired shape, is known for its high electrical conductivity, good corr...Read more -

5G and the Importance of Copper Foil in Communication Technology

Imagine a world without copper. Your phone is dead. Your girlfriend’s laptop is dead. You are lost in the middle of a deaf, blind and mute environment, which has suddenly stopped connecting information. Your parents can’t even find out what’s going on: at home the TV doesn’...Read more -

Battery copper foil Used for Electric Vehicles(EV) Civen Metal

The electric vehicle is on the verge of making a breakthrough. With uptake across the globe on the rise, it will provide major environmental advantages, particularly in metropolitan areas. Innovative business models are being developed that will increase customer adoption and address remaining co...Read more -

Application of Copper Foil in Power Battery Civen Metal

Introduction In 2021 China battery companies increased the introduction of thinner copper foil, and many companies have used their advantage by processing copper raw materials for battery production. To improve the energy density of batteries, companies are speeding up the production of thin and ...Read more -

Electrolytic Copper Foil’s Usage in Flexible Printed Circuits

Flexible printed circuit boards are a bendable type of circuit board manufactured for several reasons. Its benefits over traditional circuit boards include decreasing assembly errors, being more resilient in harsh environments, and being capable of handling more complex electronic configurations....Read more -

The Basics of Copper Foil in Lithium Ion Batteries

One of the most essential metals on the planet is copper. Without it, we are unable to do the things we take for granted such as turning on lights or watching TV. Copper are the arteries that make computers function. We wouldn’t be able to travel in cars without copper. Telecommunications w...Read more -

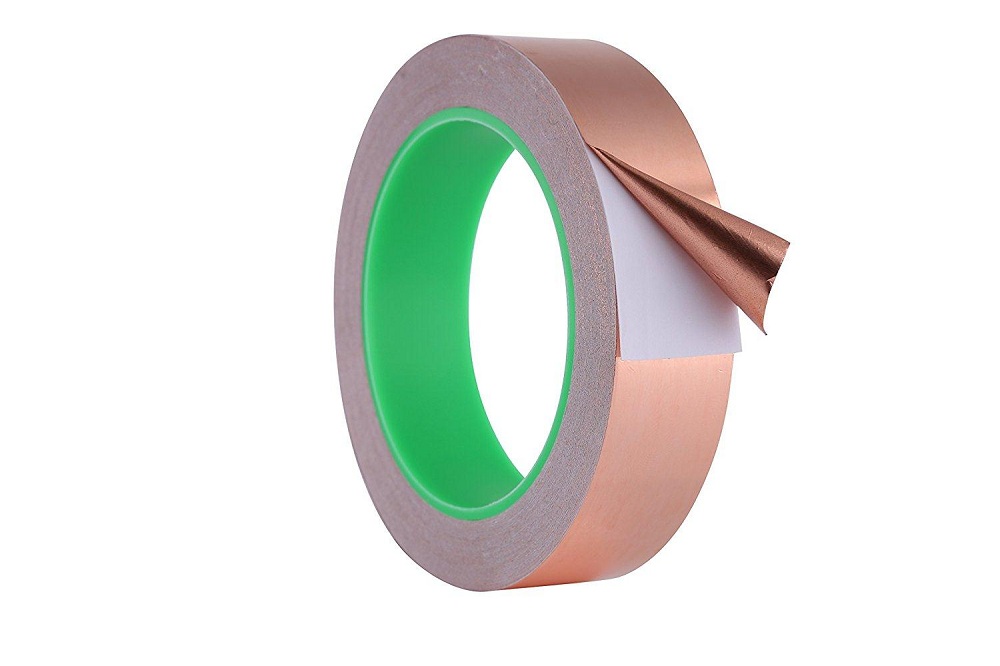

Copper Foil For Shielding-The Shielding Function Of Copper Foil For High-End Electronic Products

Wondering why Copper foil is the best shielding material? Electromagnetic and radio-frequency interference (EMI/RFI) is a major issue for shielded cable assemblies used in data transmission. The smallest disturbance could result in device failure, a reduction in signal quality, data loss, ...Read more -

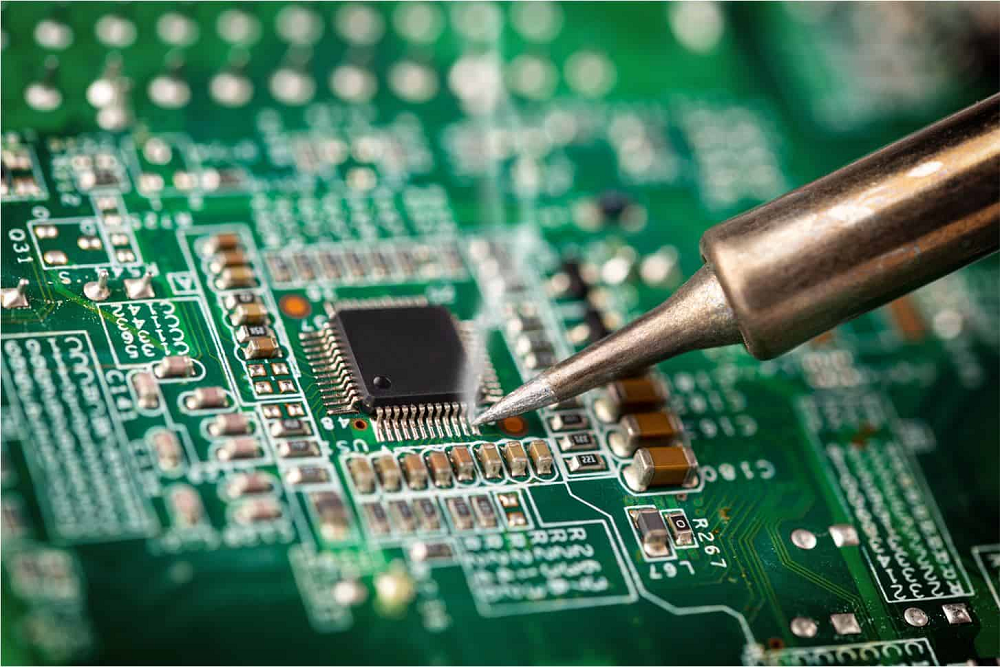

The Role of Copper Foil in the Circuit Board Industry

Copper foil for PCB Due to the increased use of electronic devices, the demand for these devices has constantly been high in the market. These devices currently surround us as we greatly depend on them for different purposes. For this reason, I bet you have come across an electronic device or us...Read more