Wondering why Copper foil is the best shielding material?

Electromagnetic and radio-frequency interference (EMI/RFI) is a major issue for shielded cable assemblies used in data transmission. The smallest disturbance could result in device failure, a reduction in signal quality, data loss, or a full disruption of the transmission. Shielding, which is a layer of insulation that contains electrical energy and is wrapped around an electrical cable to stop it from emitting or absorbing EMI/RFI, is a component of shielded cable assemblies. The most widely utilized shielding techniques, are “foil shielding” and “braided shielding.”

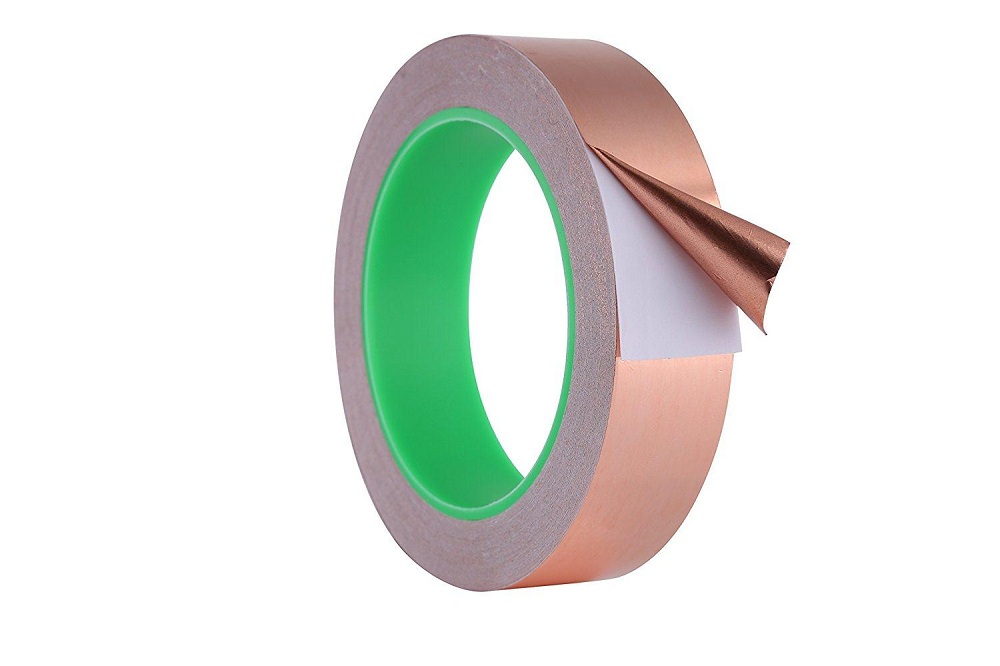

A shielded cable that uses a thin coating of copper or aluminum backing to boost longevity is known as foil shielding. A tinned copper drain wire and a foil shield work together to ground the shield.

The advantages of using copper as foil and braided shielding

The two most popular types of shielded cable used in industries are foil and braided. Both types are using copper. Foil shielding provides complete protection and is resistant to high-frequency RFI applications. Foil shield is quick, cheap, and simple to create because it is lightweight and affordable.

Mesh and flat braid shields are both available. At the time of manufacturing, flat braid made of tinned copper is rolled into braid. Its high degree of flexibility makes it an excellent protective braid for hoses and tubings. It can be used as a bonding strap for equipment in cars, planes, and ships as well as for shielding cables, ground straps, battery grounding, and battery grounding. It is suitable for any application that calls for woven, tinned copper braid and also gets rid of ignition interference. A minimum of 95% of the shield is covered by tinned copper. Weaved tinned copper shields satisfy the requirements of ASTM B-33 and QQ-W-343 type S.

Copper foil tapes’ conductive adhesive is perfect for modifying printed circuit boards, fixing security alarm circuits, and laying out and designing wiring board prototypes. It is excellent for EMI/RFI shielding cable wrapping and for ensuring electrical continuity by joining EMI/RFI shielded rooms. Additionally, it is utilized to make surface contact with non-solderable materials like plastic or aluminum and to drain static electricity. Its annealed, copper-bright hue makes it perfect for arts and crafts projects since it won’t tarnish. A thin sheet of copper or aluminum is used in foil shielding. Typically, this “foil” is attached to a polyester carrier to increase the cable’s strength. This kind of shielded cable, also referred to as “tape” shielding, completely protects the conductor wire it is wrapped around. No EMI from the environment can penetrate. However, these cables are exceedingly challenging to deal with, especially when utilizing a connector, because the foil inside the cable is so delicate. Instead of attempting to ground the cable shield completely, a drain wire will typically be employed.

Tinted copper shield is advised for greater shield coverage. Its 95 percent minimum coverage is provided by its woven, tinned copper composition. It is exceptionally flexible and has a nominal thickness of.020″, making it perfect for use as a bonding strap for marine equipment, cars, and airplanes.

Copper wires are woven into a mesh for braided insulated cables. Although less protective than foil shields, braided shields are substantially more robust. When using the connector, the braid is considerably easier to terminate and creates a low-resistance path to grounding. Depending on how firmly the braid is weaved, braided shielding typically provides 70 to 95 percent EMI protection. Because copper conducts electricity more quickly than aluminum and because braided shields are less likely to sustain internal damage, they are more effective than foil shields. Due to their superior performance and durability, braided shield cables are heavier and more expensive than tape shields.

Our company, Civen Metal, assembled the best production machinery and assembly lines in the world, as well as a sizable professional and technical workforce and first-rate management team. We follow worldwide procedures and standards for material selection, production, quality control, packaging, and transportation. Additionally, we are capable of doing independent research and development and producing unique metal materials for clients.

You can visit our website (posted below) , to discover more detailed information regarding foil tape, and tinned copper shielding, or you can call us for assistance.

https://www.civen-inc.com/

REFERENCES:

Rolled copper foils, electrolytic copper foil, coil sheet – civen. (n.d.). Civen-inc.com. Retrieved July 29, 2022, from https://www.civen-inc.com/

Post time: Aug-04-2022