Creating art for discolored glass can be tricky, especially for newbies. The choice of the best copper foil is dictated by several factors like the size and thickness of the foil. You first don’t want to acquire a copper foil that doesn’t suit the project’s needs.

Tips for selecting the ideal copper foil

Luckily, Civen Metal has great insights helpful when buying the right yet convenient copper foil to use for the project at hand. What are some important considerations to account for when choosing a suitable copper foil for discolored glass? We’ll take a look at some factors to consider before acquiring the best copper foil for a tainted glass project.

Project size

The size of the project dictates the size of copper foil suitable for use. A 3/16″ or 1/4″ copper foil is great for use of glass. Foils much wider than this range are usually cumbersome when installing. Even when used for larger glass panels, wider foils don’t work best. Considering the size of the project at hand is integral when choosing the right copper foil for discolored glass. Civec Metal provides copper foils of different sizes to cater to all projects.

Copper foil width

Copper foils that leave skinny lines aren’t effective and strong. This is because additional solder can be applied to the metal. Most artists prefer to use the 7/32″ foil but in case you change the copper foil width, more depth is required. A much thicker glass requires a foil of ¼” width. To apply additional effects, it’s prudent to trim the foil using a sharp razor blade. Also, crafting a distance in your work project is not cumbersome as the foil lines do thin with time. To achieve this, a 5/32″ or 3/16″ foil is ideal when adding the final touches.

Copper foil thickness

Copper foil is usually measured in terms of mils. Beware that cheap copper foils tend to wear and tear easily, especially when installed on corners. An original and quality copper foil doesn’t tear and is thus ideal for glass projects. The thinnest copper foil is 1 mil but most glass projects require a foil of 1.25 mils. This type of foil is resilient to tear and also ideal for installing in curved glass areas.

Type of color for the backing

Copper foil backings come in 3 diverse colors; black, silver, and copper. A suitable color backing needs to conform to the color of the color of copper foil to be utilized. For copper patina, a copper-backed foil is best for installation. Other glasses like opalescent don’t require a particular color backing since it’s hard to notice the backing. Transparent glasses require a backing that matches to stand out and be noticeable. The color of glass needs to conform to the glass to reveal attractiveness.

Project design

The project design plays a crucial role when adding personal wants and preferences. Heavier lines on the project require a much wider foil. A narrower foil is great at providing a lighter project design.

The appearance of the glass piece

Utilizing different copper foil widths on discolored glass provides an additional emphasis, especially where there is a heavy foil. Remarkably, the foil provides additional details by separating the background from the foreground. Also, it’s possible to add a subject while drawing great attention to the glass piece.

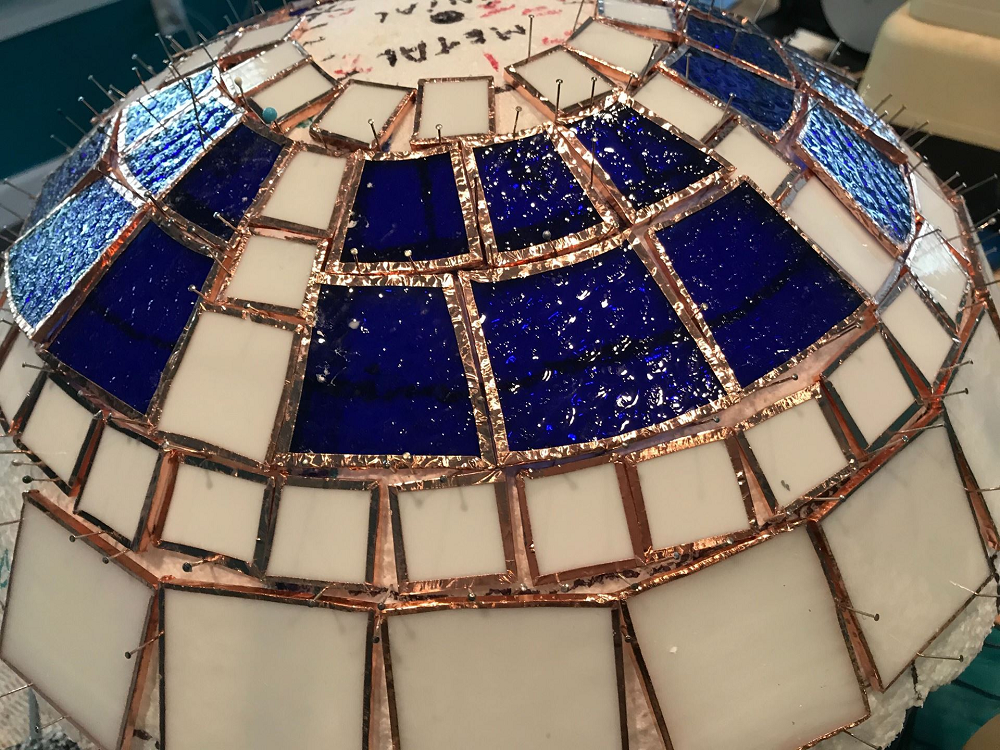

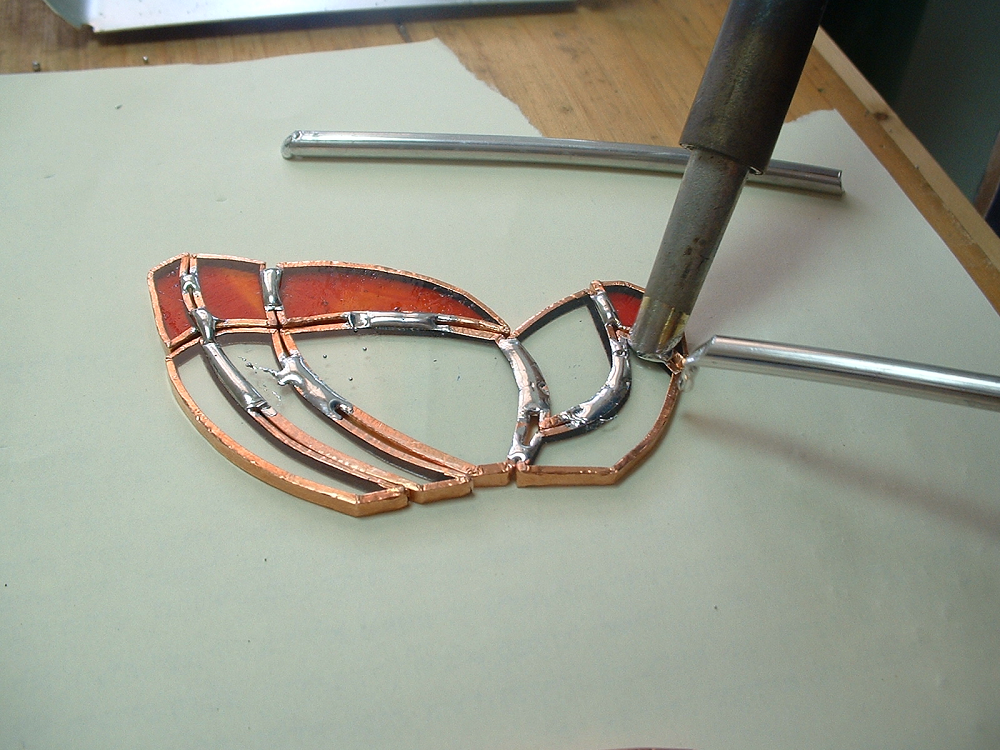

How to foil using copper foils

To start foiling, first, harness the foil away from the project surface edge. This makes the connection between the discolored glass and foils strong. This is because the foil isn’t linked from the edge where it is susceptible to becoming loose. When foiling, check for the numbered lines of the project piece and start there for proper adhesion.

Avoid soldering slowly as the glue tends to melt and thus doesn’t hold. The purpose of glue is to keep the foil intact until the final soldering. Also, adjust the width of the outside copper foil to harness the overall stability of the solder.

Ra copper foil

Ra copper foil is great when passing copper foils via two rollers. This enables the copper foil to attain a suitable thickness best for the project. Ra copper is smooth by nature and thus much more flexible, especially when rolling around curved workspaces. Importantly, the roughness of the copper foils fluctuates as a result of several factors like the pressure of rollers.

Traits of a quality copper foil

Copper foils help to connect glasses by using solder. A solder doesn’t hold when in contact with class and that’s why a copper foil is required and acts as a foundation. Cevic Metal provides the best yet quality copper foils that possess these traits.

·Flexibility: A quality copper foil needs to run smoothly more so on curved surfaces. By this, we mean the foil should be stretched with minimal effort to fit comfortably on the glass without tearing. Copper foils for tainted glasses should also be easy to maneuver when installing.

·Softness: The foil needs to be soft to stretch well on the project surface. Softer copper foils conform well with the shape of glass compared to hard foils. Importantly, not all soft foils are the best. We are a legit dealer for all glass project needs especially those requiring soft copper foils.

·Strength: A suitable copper foil needs to be strong and adhere well to the installation. Strong foils run smoothly while also eliminating any kinks.

Maintaining copper foil longer

Copper foils are susceptible to environmental conditions and protecting them is crucial. Protecting copper foils helps project one evade costs associated with getting a replacement. This is how you can lengthen the life of a copper foil.

·Store copper foils in a cool and dry place. An airtight bag is a suitable remedy to use for long use.

·Installing them in airtight cans deter moisture from affecting the appearance and quality of the copper foil.

Cevic Metal provides second-to-none copper foils suitable for both artistic and also automobile works. All products provided last longer compared to regular copper foils.

Post time: Jul-05-2022