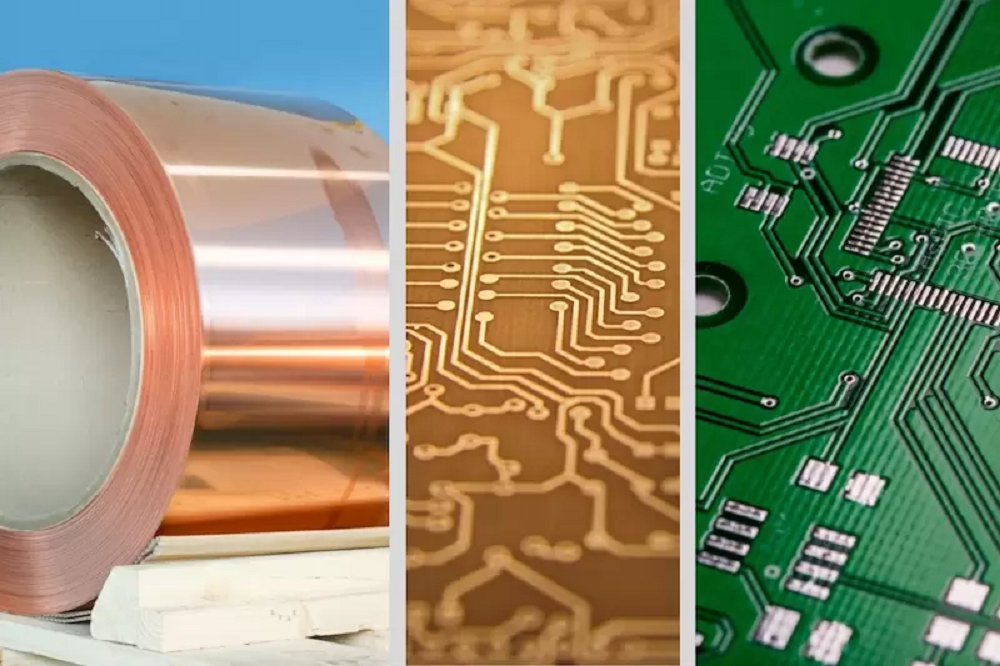

The use of copper foil in electronic products has become increasingly prevalent in recent years due to its unique properties and versatility. Copper foil, which is a thin sheet of copper that has been rolled or pressed into a desired shape, is known for its high electrical conductivity, good corrosion resistance, and ease of fabrication.

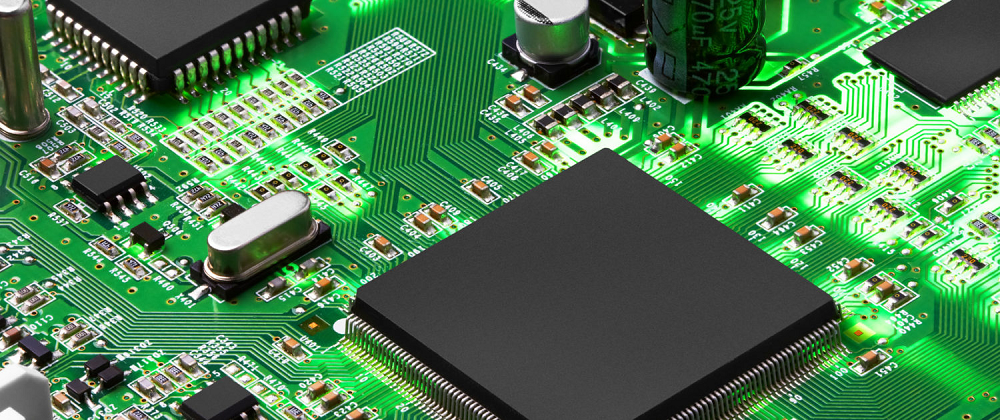

One of the main advantages of using copper foil in electronic products is its high electrical conductivity, which allows for efficient and reliable transmission of electricity. Copper foil is therefore an ideal choice for components such as wires, connectors, and circuit boards, and it is commonly used in electrical equipment, medical devices, consumer electronics, and aerospace and defense applications.

Some specific applications of copper foil in electronic products include:

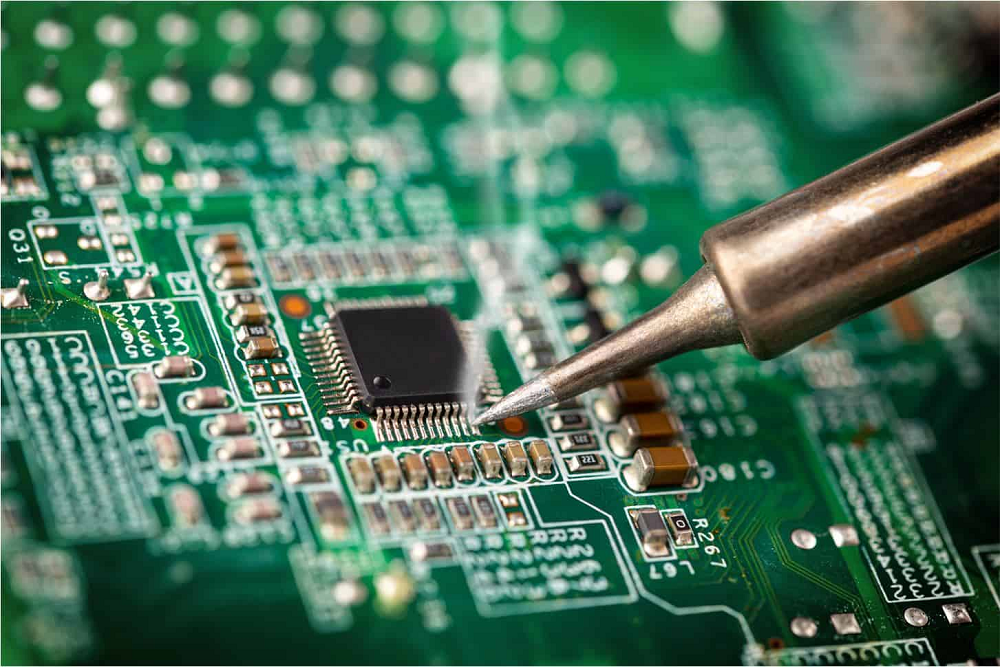

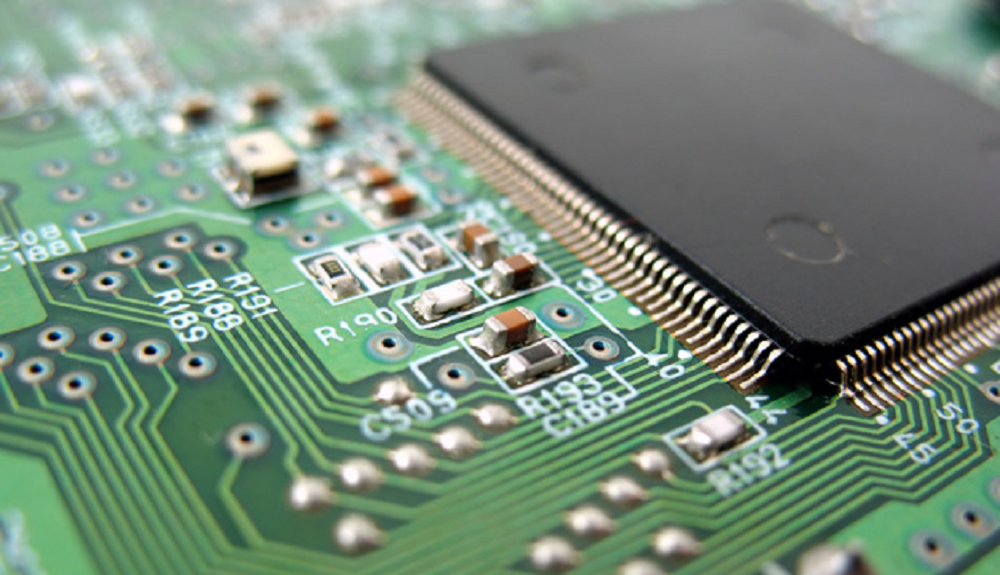

1. Electrical equipment: Copper foil is used in the production of electrical equipment such as wires, connectors, and circuit boards. For example, copper foil is used to make wire harnesses for automobiles, which are responsible for transmitting electricity throughout the vehicle. Copper foil is also used to make circuit boards for computers and other electronic devices, which are responsible for directing and controlling the flow of electricity within the device.

2. Medical devices: Copper foil is used in the production of medical devices such as defibrillators, pacemakers, and electronic stethoscopes. For example, copper foil is used to make the electrodes that are placed on a patient’s chest during defibrillation, a life-saving procedure used to restore a normal heartbeat. Copper foil is also used to make the leads that connect pacemakers to a patient’s heart, and it is used in the construction of electronic stethoscopes, which use electronic sensors to amplify and filter sound waves.

3. Consumer electronics: Copper foil is used in the production of consumer electronics such as smartphones, laptops, and tablets. For example, copper foil is used to make the printed circuit boards that are responsible for directing and controlling the flow of electricity within these devices, and it is used to make the connectors and cables that connect different components within the device. Copper foil is also used to make the antennae that allow these devices to communicate with wireless networks.

4. Aerospace and defense: Copper foil is used in the production of aerospace and defense systems such as radar and communication systems. For example, copper foil is used to make the printed circuit boards that are responsible for directing and controlling the flow of electricity within these systems, and it is used to make the connectors and cables that connect different components within the system. Copper foil is also used to make the antennae that allow these systems to communicate with other devices.

In addition to these specific applications, copper foil is also used in a wide range of other electronic products, including renewable energy systems, automotive electronics, and industrial control systems.

The connection between copper foil and electronic products is based on the unique properties and capabilities of copper foil, which make it an essential material in the production of electronic devices. Copper foil’s high electrical conductivity, corrosion resistance, versatility, and durability contribute to the reliability and performance of electronic products, and its production and processing capabilities allow manufacturers to customize and optimize the design and functionality of these products.

The production and processing of copper foil involve a variety of steps, including the sourcing of raw materials, melting and casting, rolling and annealing, and quality control and testing. These steps are carefully controlled and monitored to ensure the production of high-quality copper foil that meets industry standards. However, there are also challenges and considerations that need to be addressed when it comes to the use of copper foil in electronic products, such as the cost and availability of raw materials and the environmental impact of production.

If you are in need of metal materials for your electronic products, It is highly recommend to choose CIVEN Metal. This company specializes in the production and distribution of high-end metal materials, including copper foil. With its production bases located in various places in China, CIVEN Metal serves a wide range of industries and has established itself as a reliable and trustworthy choice for companies seeking metal materials for their electronic products. The company has a proven track record of successful partnerships and collaborations with major companies in various industries and is committed to quality and customer satisfaction, as demonstrated through its strict quality control measures and responsive customer service.

In conclusion, copper foil is a vital component in the production of electronic products due to its high electrical conductivity, good corrosion resistance, versatility, and durability. CIVEN Metal is well-positioned to continue providing high-quality metal materials and services to the electronic product industry in the future.

Post time: Dec-26-2022