New Delivery for Plate Heat Exchange Copper Foil - ED Copper Foils for FPC – CIVEN

New Delivery for Plate Heat Exchange Copper Foil - ED Copper Foils for FPC – CIVEN Detail:

Product Introduction

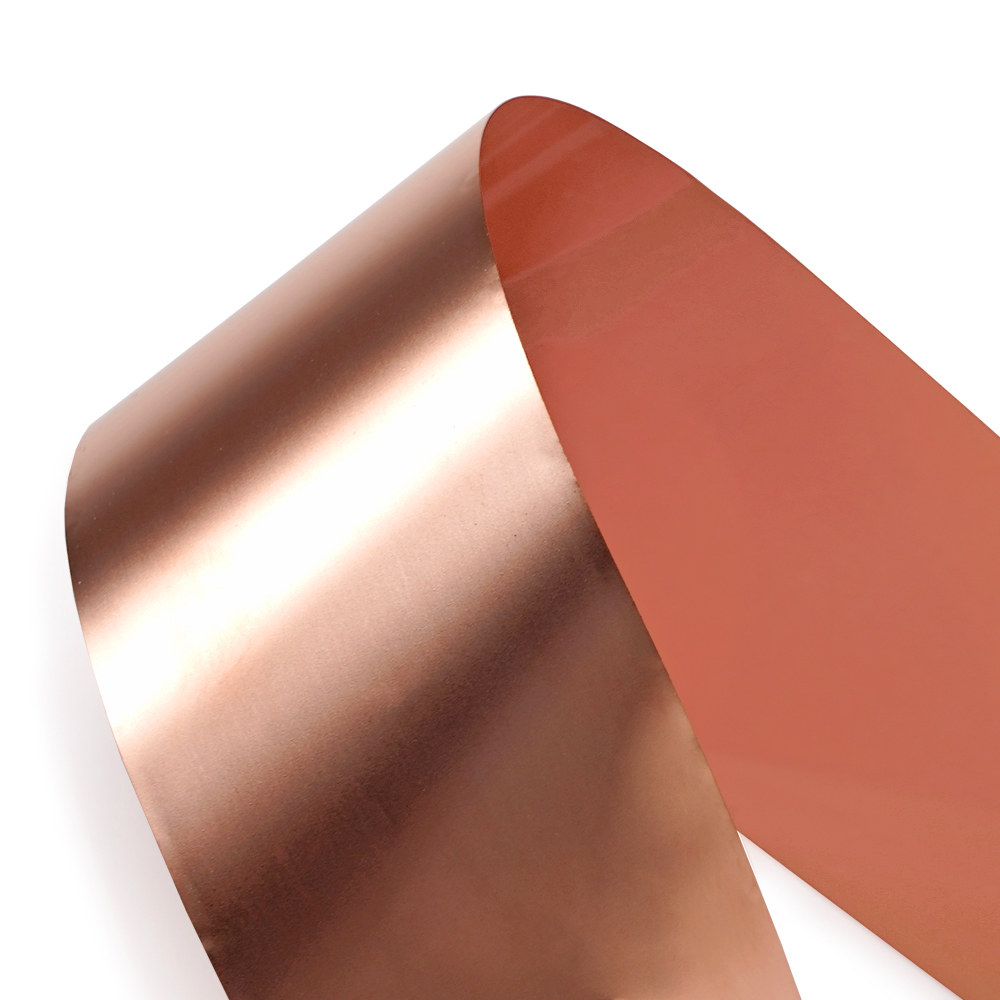

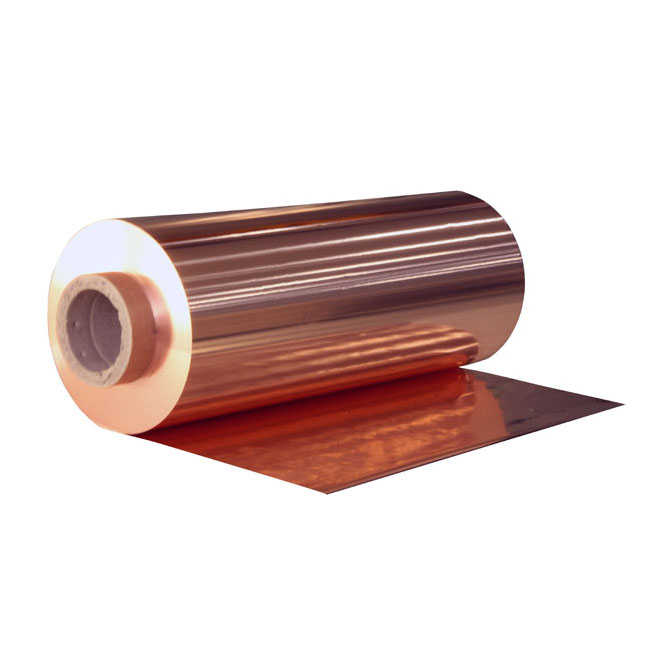

Electrolytic copper foil for FPC is specially developed and manufactured for the FPC industry (FCCL). This electrolytic copper foil has better ductility, lower roughness and better peel strength than other copper foils. At the same time, the surface finish and fineness of the copper foil is better and the folding resistance is also better than similar copper foil products. Since this copper foil is based on the electrolytic process, it does not contain grease, which makes it easier to be combined with TPI materials at high temperatures.

Dimension Range

Thickness: 9µm~35µm

Performances

The product surface is black or red, has lower surface roughness.

Applications

Flexible Copper Clad Laminate (FCCL), Fine Circuit FPC, LED coated crystal thin film.

Features

High density, high bending resistance and good etching performance.

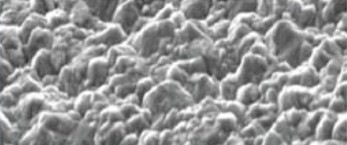

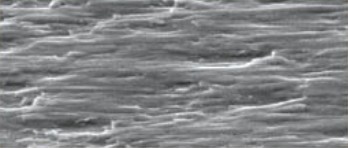

Microstructure

SEM(Before Surface Treatment)

SEM(Shiny Side after Treatment)

SEM(Rough Side after Treatment)

Table1- Performance (GB/T5230-2000、IPC-4562-2000)

|

Classification |

Unit |

9μm |

12μm |

18μm |

35μm |

|

|

Cu Content |

% |

≥99.8 |

||||

|

Area Weigth |

g/m2 |

80±3 |

107±3 |

153±5 |

283±7 |

|

|

Tensile Strength |

R.T.(23℃) |

Kg/mm2 |

≥28 |

|||

|

H.T.(180℃) |

≥15 |

≥15 |

≥15 |

≥18 |

||

|

Elongation |

R.T.(23℃) |

% |

≥5.0 |

≥5.0 |

≥6.0 |

≥10 |

|

H.T.(180℃) |

≥6.0 |

≥6.0 |

≥8.0 |

≥8.0 |

||

|

Roughness |

Shiny(Ra) |

μm |

≤0.43 |

|||

|

Matte(Rz) |

≤2.5 |

|||||

|

Peel Strength |

R.T.(23℃) |

Kg/cm |

≥0.77 |

≥0.8 |

≥0.8 |

≥0.8 |

|

Degraded rate of HCΦ(18%-1hr/25℃) |

% |

≤7.0 |

||||

|

Change of color(E-1.0hr/200℃) |

% |

Good |

||||

|

Solder Floating 290℃ |

Sec. |

≥20 |

||||

|

Appearance(Spot and copper powder) |

—- |

None |

||||

|

Pinhole |

EA |

Zero |

||||

|

Size Tolerance |

Width |

mm |

0~2mm |

|||

|

Length |

mm |

—- |

||||

|

Core |

Mm/inch |

Inside Diameter 79mm/3 inch |

||||

Note: 1. Copper foil oxidation resistance performance and surface density index can be negotiated.

2. The performance index is subject to our testing method.

3. The quality guarantee period is 90 days from the date of receipt.

Product detail pictures:

Related Product Guide:

As for competitive prices, we believe that you will be searching far and wide for anything that can beat us. We can state with absolute certainty that for such quality at such prices we are the lowest around for New Delivery for Plate Heat Exchange Copper Foil - ED Copper Foils for FPC – CIVEN , The product will supply to all over the world, such as: Tunisia, Istanbul, Nigeria, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.