Manufacturing Companies for Reverse Treat Foil - Copper Nickel Foil – CIVEN

Manufacturing Companies for Reverse Treat Foil - Copper Nickel Foil – CIVEN Detail:

Product Introduction

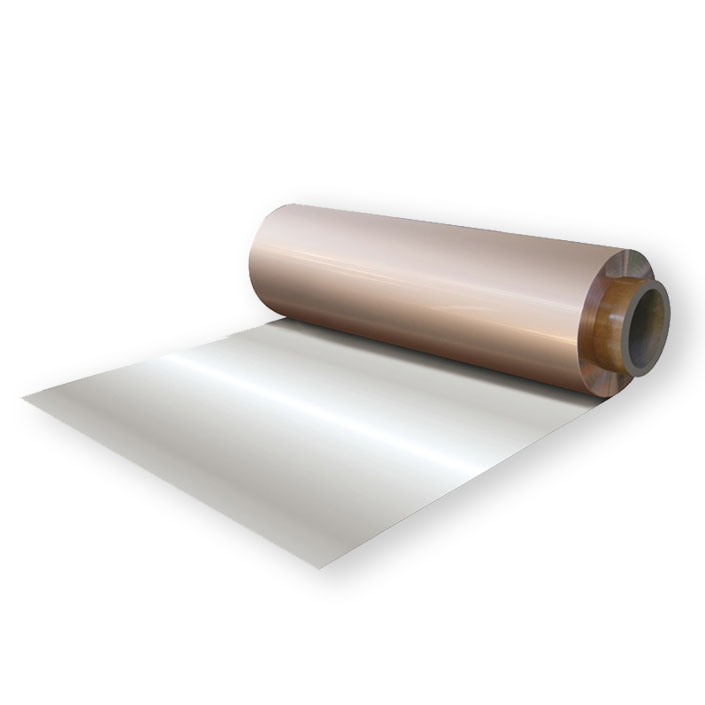

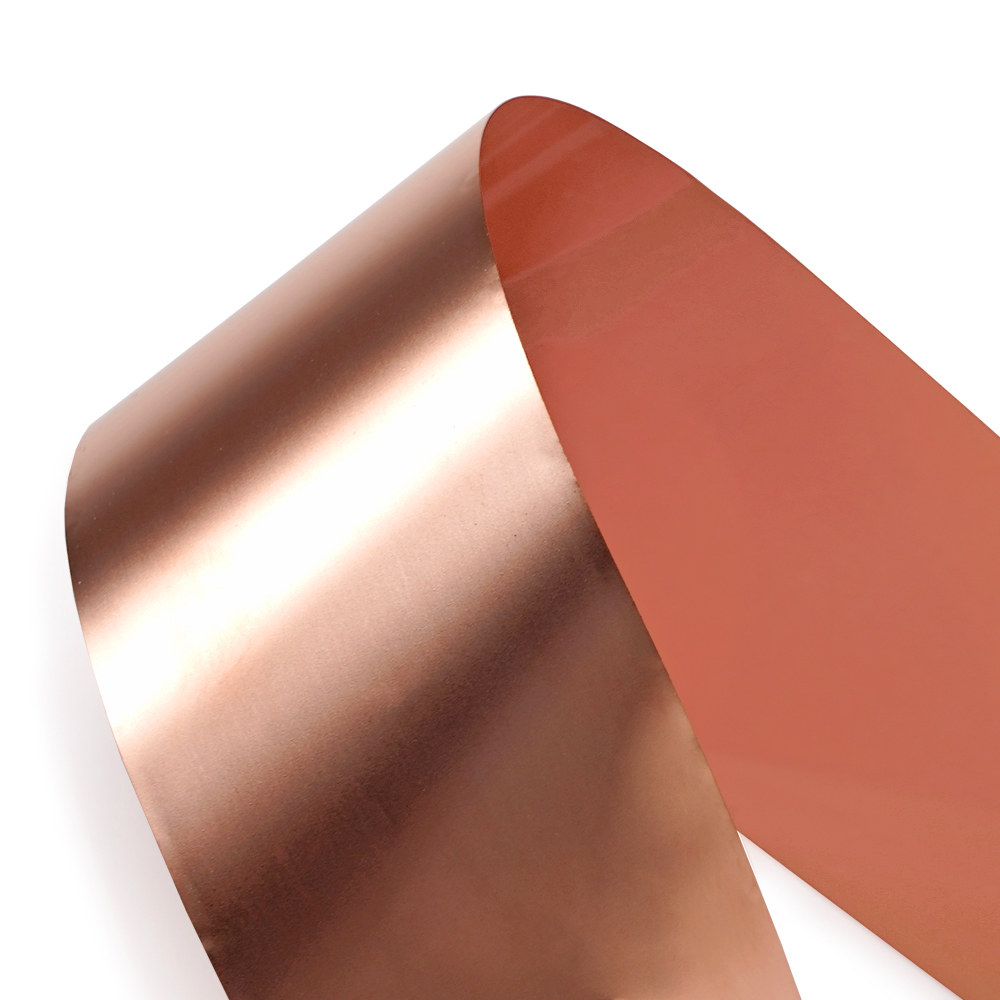

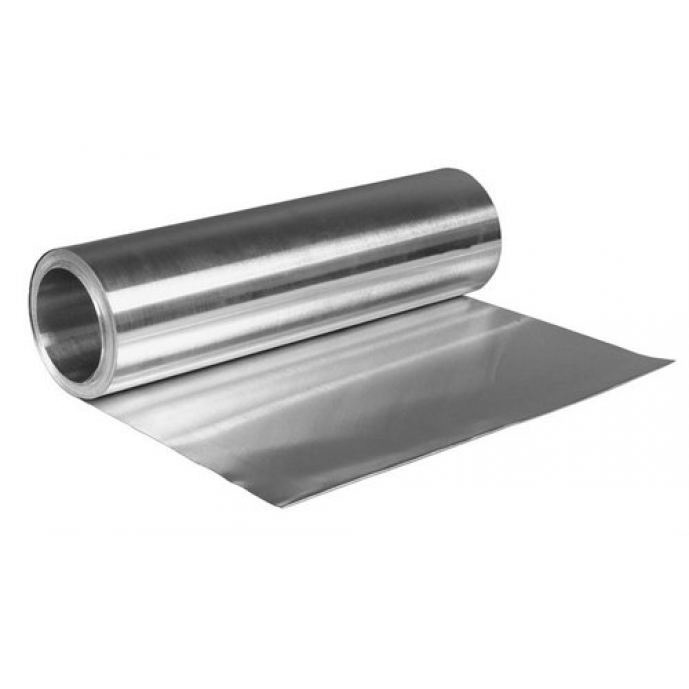

The copper-nickel alloy material is commonly referred to as white copper because of its silvery white surface. copper-nickel alloy is an alloy metal with a high resistivity and is generally used as an impedance material. It has a low resistivity temperature coefficient and a medium resistivity (resistivity of 0.48μΩ·m). Can be used over a wide temperature range. Has good processability and solderability. Suitable for use in AC circuits, as precision resistors, sliding resistors, resistance strain gauges, etc. It can also be used for thermocouples and thermocouple compensation wire material. Also, copper-nickel alloy has good corrosion resistance and can be adapted to extremely harsh working environments. The rolled copper-nickel foil from CIVEN METAL is also highly machinable and easy to shape and laminate. Due to the spherical structure of the rolled copper-nickel foil, the soft and hard state can be controlled by the annealing process, making it more suitable for a wide range of applications. CIVEN METAL can also produce copper-nickel foils in different thicknesses and widths according to customer requirements, thus reducing production costs and improving processing efficiency.

Among copper alloys, white copper is widely used as corrosion-resistant structural parts in shipbuilding, petroleum, chemical industry, construction, electric power, precision instruments, medical instruments, musical instruments and other departments because of its excellent corrosion resistance and easy molding, processing and welding. Some white copper also has special electrical properties, which can be used to make resistance elements, thermocouple materials and compensation wires. Non industrial white copper is mainly used to make decorative crafts.

Contents

|

Alloy No. |

Ni+Co |

Mn |

Cu |

Fe |

Zn |

|

ASTM C75200 |

16.5~19.5 |

0.5 |

63.5~66.5 |

0.25 |

Rem. |

|

BZn 18-26 |

16.5~19.5 |

0.5 |

53.5~56.5 |

0.25 |

Rem. |

|

BMn 40-1.5 |

39.0~41.0 |

1.0~2.0 |

Rem. |

0.5 |

— |

Specification

| Type | Coils |

| Thickness | 0.01~0.15mm |

| Width | 4.0-250mm |

| Tolerance of thickness | ≤±0.003mm |

| Tolerance of Width | ≤0.1mm |

Product detail pictures:

Related Product Guide:

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for Manufacturing Companies for Reverse Treat Foil - Copper Nickel Foil – CIVEN , The product will supply to all over the world, such as: Cairo, Malta, Guinea, If you give us a list of products you are interested in, along with makes and models, we can send you quotations. Please email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.