Manufacturing Companies for Reverse Treat Foil - Bronze Strip – CIVEN

Manufacturing Companies for Reverse Treat Foil - Bronze Strip – CIVEN Detail:

Product Introduction

Bronze strip is copper with tin, aluminum, and trace elements as raw materials, through processing by ingots, hot rolled, cold rolled, heat treatment, surface cleaning, cutting, finishing and packing, materials with high yield strength, fatigue strength, elastic properties and excellent bending formability. It has been widely used in computer CPU socket, car terminals, mobile phone keypad, electrical and other high-tech electronics connectors.

Main Technical Parameters

3-1 Chemical Composition

|

Name |

Alloy No. |

Chemical Composition( %,Max.) |

||||||||

|

Sn |

Al |

Zn |

Ni |

Fe |

Pb |

P |

Cu |

Impurity |

||

|

Tin Bronze |

QSn4-0.3 |

3.5-4.9 |

— |

0.30 |

0.2 |

0.10 |

0.05 |

0.03-0.35 |

Rem |

0.2 |

|

QSn4-3 |

3.5-4.5 |

0.002 |

2.7-3.3 |

0.2 |

0.05 |

0.02 |

0.03-0.35 |

Rem |

0.2 |

|

|

QSn6.5-0.1 |

6.0-7.0 |

0.002 |

0.3 |

0.2 |

0.02 |

0.02 |

0.1-0.25 |

Rem |

0.1 |

|

|

QSn8-0.3 |

7.0-9.0 |

—— |

0.2 |

0.2 |

0.10 |

0.05 |

0.03-0.35 |

Rem |

0.1 |

|

|

Aluminum Bronze |

QAl5 |

0.1 |

4.0-6.0 |

0.5 |

0.5 |

0.5 |

0.03 |

0.01 |

Rem |

1.6 |

|

QAl7 |

—– |

6.0-8.5 |

0.2 |

0.5 |

0.5 |

0.02 |

—— |

Rem |

—— |

|

|

QAl9-2 |

0.1 |

8.0-10.0 |

1.0 |

0.5 |

0.5 |

0.03 |

0.01 |

Rem |

1.7 |

|

|

Name |

Alloy No. |

Chemical Composition( %,Max.) |

|||||||||

|

Be |

Al |

Si |

Ni |

Fe |

Pb |

Ti |

Co |

Cu |

Imputrity |

||

|

Beryllium Bronze |

QBe2 |

1.8-2.1 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

— |

— |

Rem |

0.5 |

|

QBe1.9 |

1.85-2.1 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

0.10-0.25 |

— |

Rem |

0.5 |

|

|

QBe1.7 |

1.6-1.85 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

0.10-0.25 |

— |

Rem |

0.5 |

|

|

QBe0.6-2.5 |

0.4-0.7 |

0.20 |

0.20 |

—— |

0.10 |

— |

— |

2.4-2.7 |

Rem |

— |

|

|

QBe0.4-1.8 |

0.2-0.6 |

0.20 |

0.20 |

1.4-2.2 |

0.10 |

— |

— |

0.30 |

Rem |

— |

|

|

QBe0.3-1.5 |

0.25-0.5 |

0.20 |

0.20 |

—— |

0.10 |

— |

— |

1.4-1.7 |

Rem |

— |

|

3-2 Alloy Table

|

Name |

China |

ISO |

ASTM |

JIS |

|

Tin Bronze |

QSn4-0.3 |

CuSn4 |

C51100 |

C5101 |

|

QSn4-3 |

CuSn4Zn2 |

— |

— |

|

|

QSn6.5-0.1 |

CuSn6 |

C51900 |

C5191 |

|

|

QSn8-0.3 |

CuSn8 |

C52100 |

C5210 |

|

|

Aluminum Bronze |

QAl5 |

CuAl5 |

C60600 |

—— |

|

QAl7 |

CuAl7 |

C61000 |

—— |

|

|

QAl9-2 |

CuAl9Mn2 |

—— |

—— |

|

|

Beryllium Bronze |

QBe2 |

CuBe2 |

C17200 |

C1720 |

|

QBe1.9 |

—— |

—— |

—— |

|

|

QBe1.7 |

CuBe1.7 |

C17000 |

C1700 |

|

|

QBe0.6-2.5 |

—— |

C17500 |

C1750 |

|

|

QBe0.4-1.8 |

—— |

C17510 |

C1751 |

|

|

QBe0.3-1.5 |

—— |

C17600 |

C1760 |

Main Technical Parameters

3-3-1Specification Unit: mm

|

Name |

Alloy No.(China) |

Temper |

Size(mm) |

|

|

Thickness |

Width |

|||

|

Tin Bronze Strip |

QSn4-3 QSn4-0.3 QSn6.5-0.1QSn8-0.3 |

O 1/2H H EH |

>0.12~2.0 |

≤600 |

|

O H EH |

||||

|

Aluminum Bronze Strip |

QA15 QA17 QA19-2 |

O H |

>0.2~1.2 |

80~300 |

|

1/2H H |

||||

|

O H EH |

>0.2~1.2 |

80~300 |

||

|

Beryllium Bronze Strip |

QBe2 QBe1.9 QBe1.7 QBe0.6-2.5 QBe0.4-1.8 QBe0.3-1.5 |

O |

0.05-1.5 |

10~340 |

|

H |

||||

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

3-3-2 Tolerance Unit: mm

|

Thickness |

Width |

|||

|

Thickness Allow Deviation± |

Width Allow Deviation ± |

|||

|

<300 |

<600 |

<400 |

<600 |

|

|

0.05~0.1 |

0.005 |

—– |

0.2 |

—– |

|

0.1~0.3 |

0.008 |

0.015 |

0.3 |

0.4 |

|

0.3~0.5 |

0.015 |

0.020 |

0.3 |

0.5 |

|

0.5~0.8 |

0.020 |

0.030 |

0.3 |

0.5 |

|

0.8~1.2 |

0.030 |

0.040 |

0.4 |

0.6 |

3-3-3 Mechanical Performance:

|

Temper |

Tensile Strength N/mm2 |

Elongation ≥% |

Hardness HV |

|

|

M |

(O) |

≥295 |

40 |

—— |

|

Y4 |

(1/4H) |

390-510 |

35 |

100-160 |

|

Y2 |

(1/2H) |

440-570 |

10 |

160-205 |

|

Y |

(H) |

540-690 |

8 |

180-230 |

|

T |

(EH) |

≥640 |

5 |

≥200 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

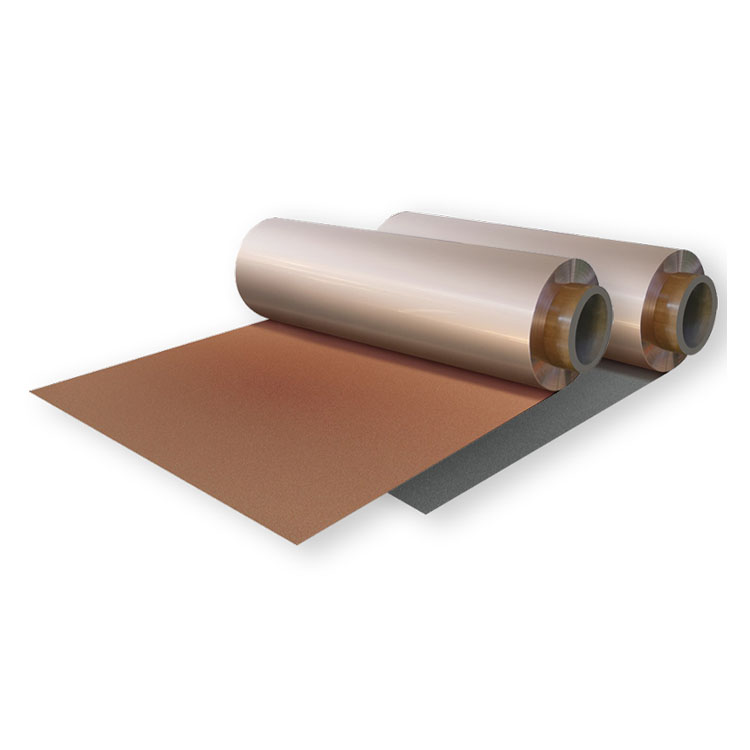

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of Manufacturing Companies for Reverse Treat Foil - Bronze Strip – CIVEN , The product will supply to all over the world, such as: Georgia, San Francisco, Mozambique, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.