Low MOQ for Flexible Printed Circuits Copper Foil - Nickel Plated Copper Foil – CIVEN

Low MOQ for Flexible Printed Circuits Copper Foil - Nickel Plated Copper Foil – CIVEN Detail:

Product Introduction

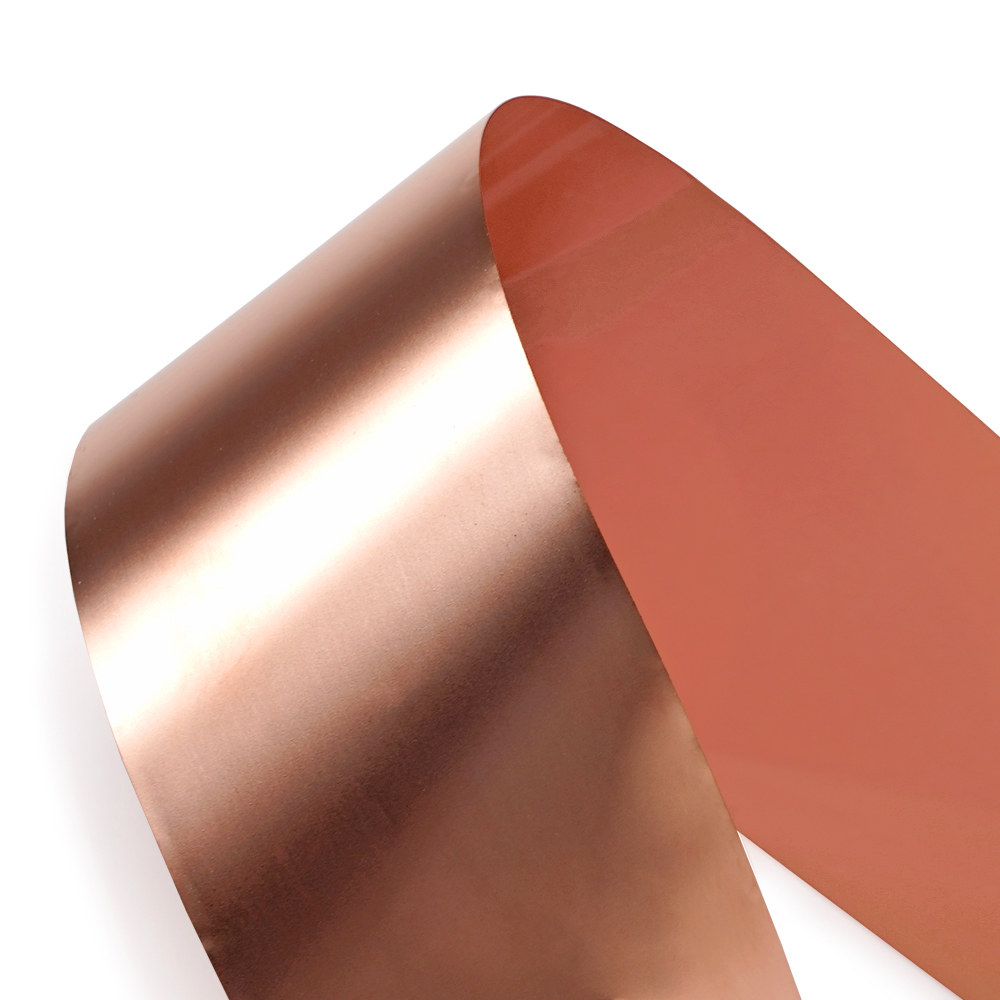

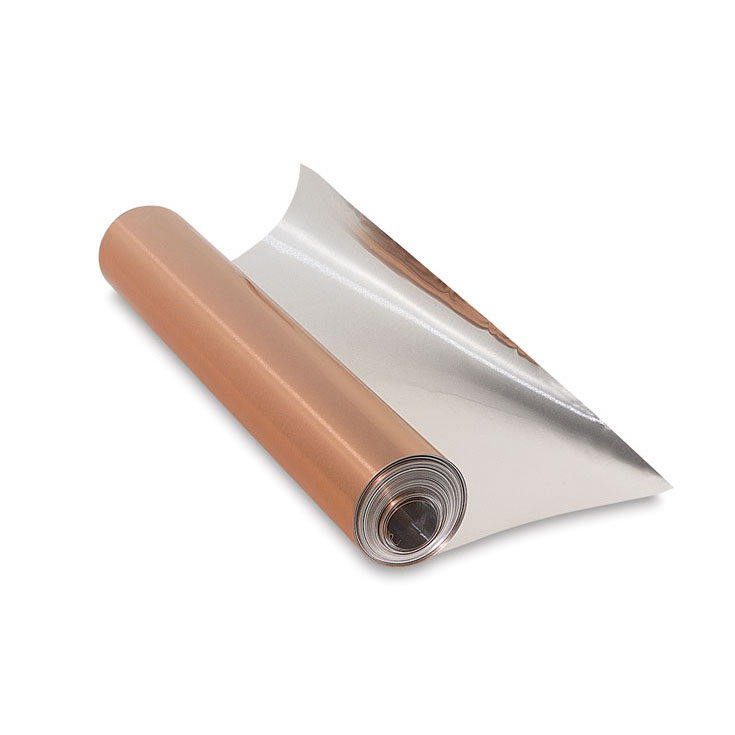

Nickel metal has high stability in air, strong passivation ability, can form a very thin passivation film in air, can resist the corrosion of alkali and acids, so that the product is chemically stable in work and alkaline environment, not easy to discolor, can only be oxidized above 600 ℃; nickel plating layer has strong adhesion, not easy to fall off; nickel plating layer can make the surface of material harder, can improve the product wear resistance and acid and alkali corrosion resistance, the product wear resistance, corrosion, rust prevention performance is excellent. Due to the high surface hardness of nickel plated products, nickel plated crystals are extremely fine, with high polishability, polishing can reach the mirror appearance, in the atmosphere can be maintained in the long term clean, so it is also commonly used for decoration. The nickel plated copper foil produced by CIVEN METAL has a very good surface finish and a flat shape. They are also degreased and can be easily laminated with other materials. At the same time, we can also customize our nickel-plated copper foil by annealing and slitting according to customer requirements.

Base Material

● High-precision Rolled Copper Foil (JIS:C1100/ASTM:C11000) Cu content more than 99.96%

Base Material Thickness Range

● 0.012mm~0.15mm (0.00047inches~0.0059inches)

Base Material Width Range

● ≤600mm (≤23.62inches)

Base Material Temper

● According to customer requirements

Application

● Electrical appliances, electronics, batteries, communications, hardware and other industries;

Performance Parameters

|

Items |

Wieldable Nickel Plating |

Non-weld Nickel Plating |

|

Width Range |

≤600mm (≤23.62inches) |

|

|

Thickness Range |

0.012~0.15mm (0.00047inches~0.0059inches) |

|

|

Nickel Layer Thickness |

≥0.4µm |

≥0.2µm |

|

Nickel Content of Nickel Layer |

80~90% (Can adjust nickel content according to customer welding process) |

100% Pure Nickel |

|

Surface Resistance of Nickel Layer (Ω) |

≤0.1 |

0.05~0.07 |

|

Adhesion |

5B |

|

|

Tensile Strength |

Base Material Performance Attenuation after Plating ≤10% |

|

|

Elongation |

Base Material Performance Attenuation after Plating ≤6% |

|

Product detail pictures:

Related Product Guide:

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Low MOQ for Flexible Printed Circuits Copper Foil - Nickel Plated Copper Foil – CIVEN , The product will supply to all over the world, such as: Sheffield, Sacramento, Paraguay, In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.