Good Wholesale Vendors Annealed Rolled Copper Foil - RA Copper Foil – CIVEN

Good Wholesale Vendors Annealed Rolled Copper Foil - RA Copper Foil – CIVEN Detail:

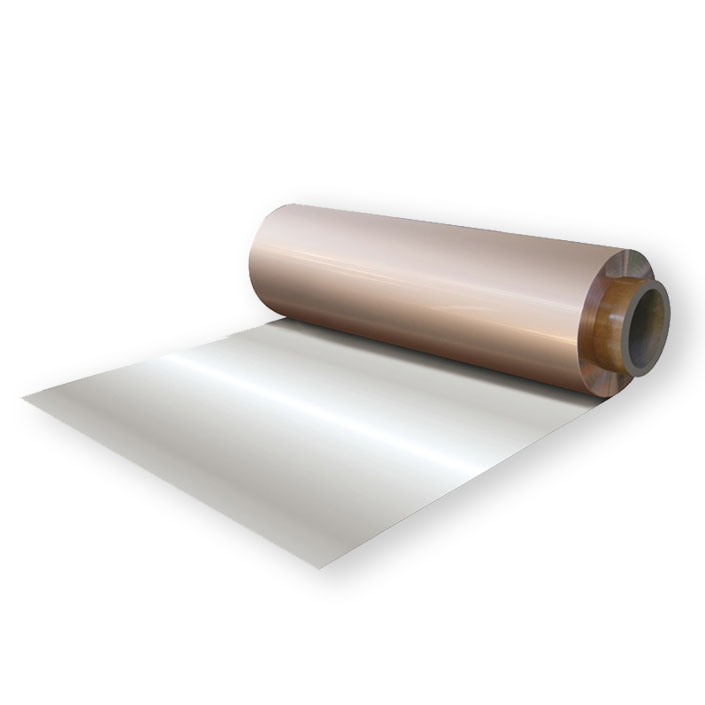

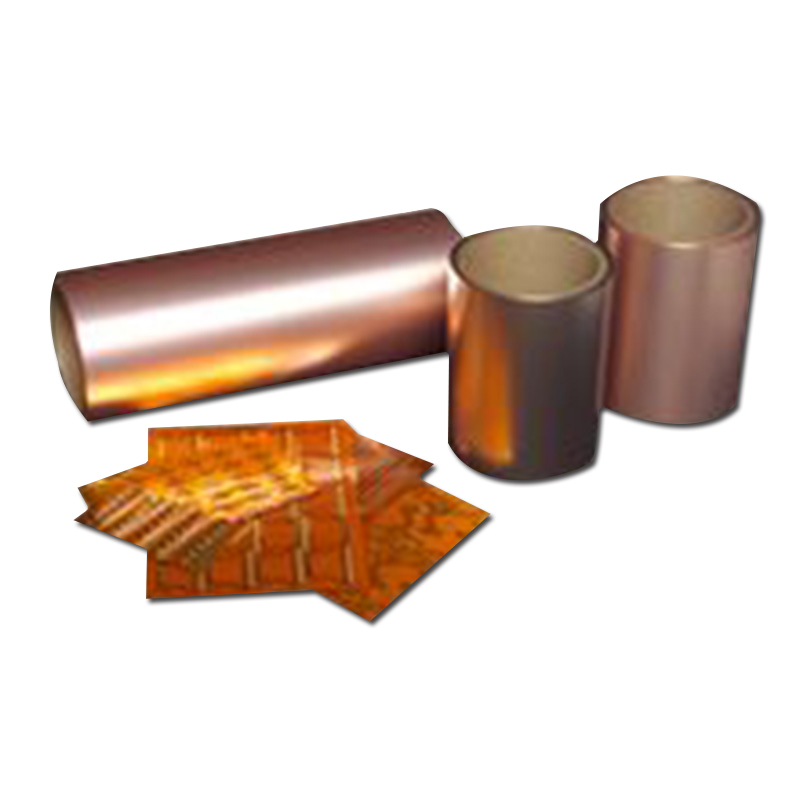

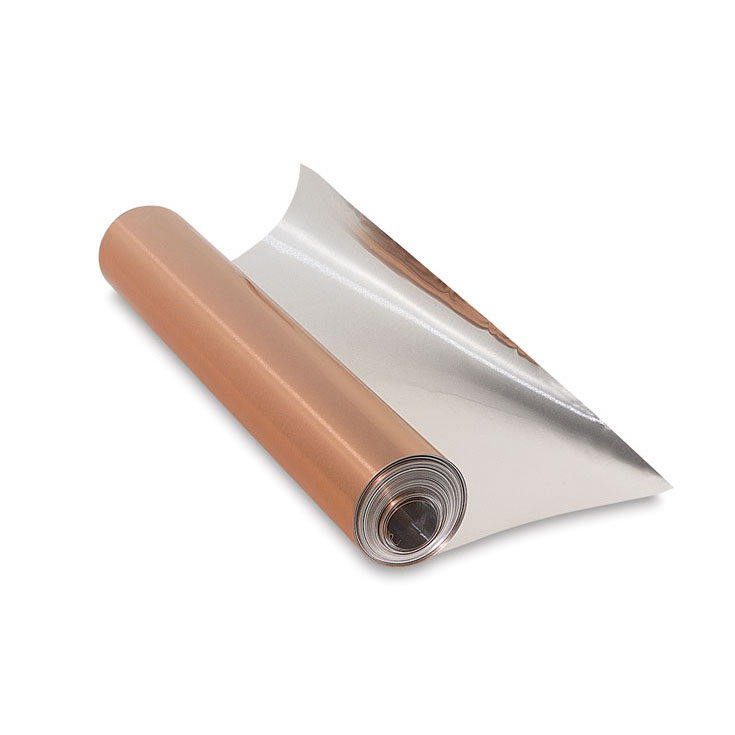

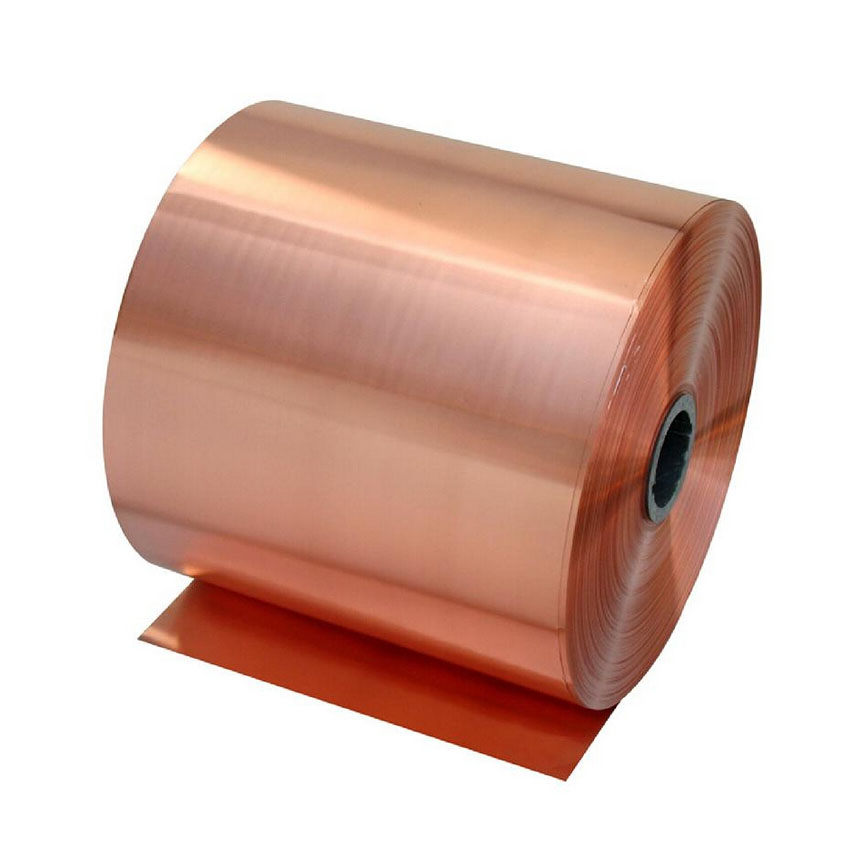

Rolled Copper Foil

The metal material with the highest copper content is called pure copper. It is also commonly known as red copper because of its surface appears reddish-purple colour. Copper has a high degree of flexibility and ductility. It also has excellent electrical and thermal conductivity. The copper foil produced by CIVEN METAL not only has high purity and low impurity characteristics, but also has a smooth surface finish, flat sheet shape and very good uniformity. They are suitable for use as electrical, thermal and electromagnetic shielding materials. The rolled copper foil from CIVEN METAL is also highly machinable and easy to shape and laminate. Due to the spherical structure of the rolled copper foil, the soft and hard state can be controlled by the annealing process, making it more suitable for a wide range of applications. CIVEN METAL can also produce copper foils in different thicknesses and widths according to customer requirements, thus reducing production costs and improving processing efficiency.

| Base Material | C11000 Copper, Cu > 99.90% |

| Thickness Range | 0.01mm-0.15mm (0.0004inch~0.006inch) |

| Width Range | 4mm-400mm(0.16inch~16inch) |

| Temper | Hard, Half Hard, Soft |

| Application | Transformer, Copper Flexible Connector, CCL, FCCL, PCB, Geothermal Film, Construction, Decoration etc. |

|

GB |

ALLOY NO. |

SIZE (mm) |

||||

|

(ISO) |

(ASMT) |

(JIS) |

(BIS) |

(DIN) |

||

|

T2 |

Cu-ETP |

C11000 |

C1100 |

C101 |

R-Cu57 |

Thickness: 0.01-0.15/Max Width: 400 |

|

TU2 |

Cu-OF |

C10200 |

C1020 |

Cu-OFC |

OF-Cu |

|

Mechanical Properties

|

Temper |

JIS Temper |

Tensile Strength Rm/N/mm 2 |

Elongation A50/% |

Hardness HV |

|

M |

O |

220~275 |

≥ 15 |

40~60 |

|

Y2 |

1/4H |

240~300 |

≥ 9 |

55~85 |

|

Y |

H |

330~450 |

- |

80~150 |

Note: We can provide products with other properties according to customers` requirements.

Physical Properties

| Density | 8.9g/cm3 |

| Electrical conductivity (20°C) | min 90%IACS for annealed to temper min 80%IACS for rolled to temper |

| Thermal conductivity (20°C) | 390W/(m°C) |

| Elastic modulus | 118000N/m |

| Softening temperature | ≥380°C |

Sizes and Tolerances (mm)

|

Thickness |

Thickness Tolerances |

Width |

Width Tolerances |

|

0.01~0.015 |

± 0.002 |

4~250 |

± 0.1 |

|

> 0.018~0.10 |

± 0.003 |

4~400 |

|

|

> 0.10~0.15 |

± 0.005 |

4~400 |

Specifications Available (mm)

|

Thickness |

Width |

Temper |

|

0.01~0.015 |

4~250 |

O,H |

|

> 0.018~0.10 |

4~400 |

O,H |

|

> 0.10~0.15 |

4~400 |

O,1/2H,H |

Carried Standard(Latest)

|

Nations |

Standard No. |

Standard Name |

|

China |

GB/T2059–2000 | CHINA’S NATIONAL STANDARD |

|

Japan |

JIS H3100 :2000 | COPPER AND COPPER ALLOY SHEETS,PLATES AND STRIPS |

|

U.S.A |

ASTM B36/B 36M -01 | STANDARD SPECIFICATION FOR BRASS,PLATE,SHEET,STRIP AND ROLLED BAR |

|

Germany |

DIN-EN 1652:1997 | COPPER AND COPPER ALLOYS PLATE,SHEET,STRIP AND CIRCLES FOR GENERAL PURPOSES |

| DIN-EN 1758 :1997 | COPPER AND COPPER ALLOYS STRIP FOR LEADFRAMES | |

|

SEMI |

SEMI G4-0302 | SPECIFICATION FOR INTERGRATED CIRCUIT LEADFRAME MATERIALS USED IN THE PRODUCTION OF STAMPED LEADFRAMES |

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for Good Wholesale Vendors Annealed Rolled Copper Foil - RA Copper Foil – CIVEN , The product will supply to all over the world, such as: Italy, El Salvador, Sweden, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.