Factory making Brass Sheets - ED Copper Foils for FPC – CIVEN

Factory making Brass Sheets - ED Copper Foils for FPC – CIVEN Detail:

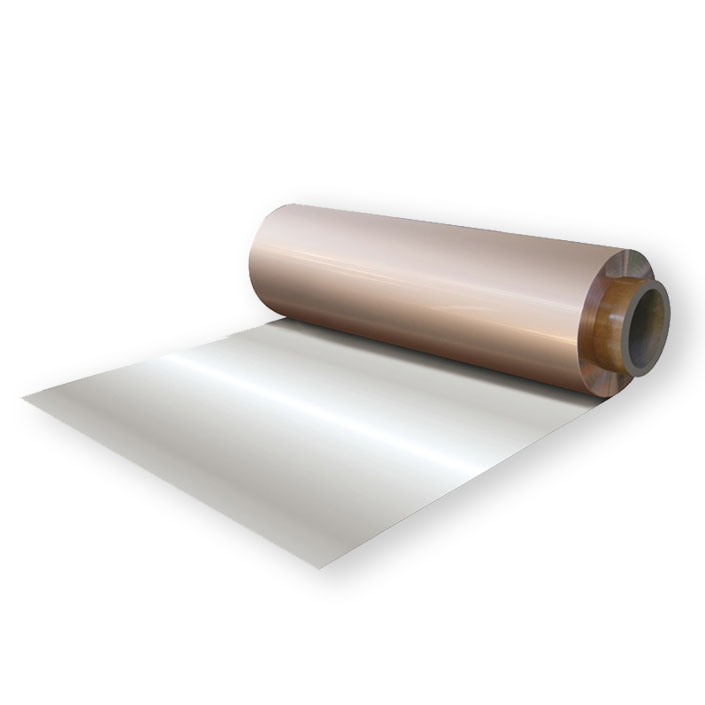

Product Introduction

Electrolytic copper foil for FPC is specially developed and manufactured for the FPC industry (FCCL). This electrolytic copper foil has better ductility, lower roughness and better peel strength than other copper foils. At the same time, the surface finish and fineness of the copper foil is better and the folding resistance is also better than similar copper foil products. Since this copper foil is based on the electrolytic process, it does not contain grease, which makes it easier to be combined with TPI materials at high temperatures.

Dimension Range

Thickness: 9µm~35µm

Performances

The product surface is black or red, has lower surface roughness.

Applications

Flexible Copper Clad Laminate (FCCL), Fine Circuit FPC, LED coated crystal thin film.

Features

High density, high bending resistance and good etching performance.

Microstructure

SEM(Before Surface Treatment)

SEM(Shiny Side after Treatment)

SEM(Rough Side after Treatment)

Table1- Performance (GB/T5230-2000、IPC-4562-2000)

|

Classification |

Unit |

9μm |

12μm |

18μm |

35μm |

|

|

Cu Content |

% |

≥99.8 |

||||

|

Area Weigth |

g/m2 |

80±3 |

107±3 |

153±5 |

283±7 |

|

|

Tensile Strength |

R.T.(23℃) |

Kg/mm2 |

≥28 |

|||

|

H.T.(180℃) |

≥15 |

≥15 |

≥15 |

≥18 |

||

|

Elongation |

R.T.(23℃) |

% |

≥5.0 |

≥5.0 |

≥6.0 |

≥10 |

|

H.T.(180℃) |

≥6.0 |

≥6.0 |

≥8.0 |

≥8.0 |

||

|

Roughness |

Shiny(Ra) |

μm |

≤0.43 |

|||

|

Matte(Rz) |

≤2.5 |

|||||

|

Peel Strength |

R.T.(23℃) |

Kg/cm |

≥0.77 |

≥0.8 |

≥0.8 |

≥0.8 |

|

Degraded rate of HCΦ(18%-1hr/25℃) |

% |

≤7.0 |

||||

|

Change of color(E-1.0hr/200℃) |

% |

Good |

||||

|

Solder Floating 290℃ |

Sec. |

≥20 |

||||

|

Appearance(Spot and copper powder) |

—- |

None |

||||

|

Pinhole |

EA |

Zero |

||||

|

Size Tolerance |

Width |

mm |

0~2mm |

|||

|

Length |

mm |

—- |

||||

|

Core |

Mm/inch |

Inside Diameter 79mm/3 inch |

||||

Note: 1. Copper foil oxidation resistance performance and surface density index can be negotiated.

2. The performance index is subject to our testing method.

3. The quality guarantee period is 90 days from the date of receipt.

Product detail pictures:

Related Product Guide:

With dependable high quality approach, great reputation and excellent customer support, the series of products and solutions produced by our firm are exported to lots of countries and regions for Factory making Brass Sheets - ED Copper Foils for FPC – CIVEN , The product will supply to all over the world, such as: United States, Russia, Senegal, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!