Factory directly supply Thin Brass Strips - Bronze Strip – CIVEN

Factory directly supply Thin Brass Strips - Bronze Strip – CIVEN Detail:

Product Introduction

Bronze strip is copper with tin, aluminum, and trace elements as raw materials, through processing by ingots, hot rolled, cold rolled, heat treatment, surface cleaning, cutting, finishing and packing, materials with high yield strength, fatigue strength, elastic properties and excellent bending formability. It has been widely used in computer CPU socket, car terminals, mobile phone keypad, electrical and other high-tech electronics connectors.

Main Technical Parameters

3-1 Chemical Composition

|

Name |

Alloy No. |

Chemical Composition( %,Max.) |

||||||||

|

Sn |

Al |

Zn |

Ni |

Fe |

Pb |

P |

Cu |

Impurity |

||

|

Tin Bronze |

QSn4-0.3 |

3.5-4.9 |

— |

0.30 |

0.2 |

0.10 |

0.05 |

0.03-0.35 |

Rem |

0.2 |

|

QSn4-3 |

3.5-4.5 |

0.002 |

2.7-3.3 |

0.2 |

0.05 |

0.02 |

0.03-0.35 |

Rem |

0.2 |

|

|

QSn6.5-0.1 |

6.0-7.0 |

0.002 |

0.3 |

0.2 |

0.02 |

0.02 |

0.1-0.25 |

Rem |

0.1 |

|

|

QSn8-0.3 |

7.0-9.0 |

—— |

0.2 |

0.2 |

0.10 |

0.05 |

0.03-0.35 |

Rem |

0.1 |

|

|

Aluminum Bronze |

QAl5 |

0.1 |

4.0-6.0 |

0.5 |

0.5 |

0.5 |

0.03 |

0.01 |

Rem |

1.6 |

|

QAl7 |

—– |

6.0-8.5 |

0.2 |

0.5 |

0.5 |

0.02 |

—— |

Rem |

—— |

|

|

QAl9-2 |

0.1 |

8.0-10.0 |

1.0 |

0.5 |

0.5 |

0.03 |

0.01 |

Rem |

1.7 |

|

|

Name |

Alloy No. |

Chemical Composition( %,Max.) |

|||||||||

|

Be |

Al |

Si |

Ni |

Fe |

Pb |

Ti |

Co |

Cu |

Imputrity |

||

|

Beryllium Bronze |

QBe2 |

1.8-2.1 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

— |

— |

Rem |

0.5 |

|

QBe1.9 |

1.85-2.1 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

0.10-0.25 |

— |

Rem |

0.5 |

|

|

QBe1.7 |

1.6-1.85 |

0.15 |

0.15 |

0.2-0.4 |

0.15 |

0.005 |

0.10-0.25 |

— |

Rem |

0.5 |

|

|

QBe0.6-2.5 |

0.4-0.7 |

0.20 |

0.20 |

—— |

0.10 |

— |

— |

2.4-2.7 |

Rem |

— |

|

|

QBe0.4-1.8 |

0.2-0.6 |

0.20 |

0.20 |

1.4-2.2 |

0.10 |

— |

— |

0.30 |

Rem |

— |

|

|

QBe0.3-1.5 |

0.25-0.5 |

0.20 |

0.20 |

—— |

0.10 |

— |

— |

1.4-1.7 |

Rem |

— |

|

3-2 Alloy Table

|

Name |

China |

ISO |

ASTM |

JIS |

|

Tin Bronze |

QSn4-0.3 |

CuSn4 |

C51100 |

C5101 |

|

QSn4-3 |

CuSn4Zn2 |

— |

— |

|

|

QSn6.5-0.1 |

CuSn6 |

C51900 |

C5191 |

|

|

QSn8-0.3 |

CuSn8 |

C52100 |

C5210 |

|

|

Aluminum Bronze |

QAl5 |

CuAl5 |

C60600 |

—— |

|

QAl7 |

CuAl7 |

C61000 |

—— |

|

|

QAl9-2 |

CuAl9Mn2 |

—— |

—— |

|

|

Beryllium Bronze |

QBe2 |

CuBe2 |

C17200 |

C1720 |

|

QBe1.9 |

—— |

—— |

—— |

|

|

QBe1.7 |

CuBe1.7 |

C17000 |

C1700 |

|

|

QBe0.6-2.5 |

—— |

C17500 |

C1750 |

|

|

QBe0.4-1.8 |

—— |

C17510 |

C1751 |

|

|

QBe0.3-1.5 |

—— |

C17600 |

C1760 |

Main Technical Parameters

3-3-1Specification Unit: mm

|

Name |

Alloy No.(China) |

Temper |

Size(mm) |

|

|

Thickness |

Width |

|||

|

Tin Bronze Strip |

QSn4-3 QSn4-0.3 QSn6.5-0.1QSn8-0.3 |

O 1/2H H EH |

>0.12~2.0 |

≤600 |

|

O H EH |

||||

|

Aluminum Bronze Strip |

QA15 QA17 QA19-2 |

O H |

>0.2~1.2 |

80~300 |

|

1/2H H |

||||

|

O H EH |

>0.2~1.2 |

80~300 |

||

|

Beryllium Bronze Strip |

QBe2 QBe1.9 QBe1.7 QBe0.6-2.5 QBe0.4-1.8 QBe0.3-1.5 |

O |

0.05-1.5 |

10~340 |

|

H |

||||

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

3-3-2 Tolerance Unit: mm

|

Thickness |

Width |

|||

|

Thickness Allow Deviation± |

Width Allow Deviation ± |

|||

|

<300 |

<600 |

<400 |

<600 |

|

|

0.05~0.1 |

0.005 |

—– |

0.2 |

—– |

|

0.1~0.3 |

0.008 |

0.015 |

0.3 |

0.4 |

|

0.3~0.5 |

0.015 |

0.020 |

0.3 |

0.5 |

|

0.5~0.8 |

0.020 |

0.030 |

0.3 |

0.5 |

|

0.8~1.2 |

0.030 |

0.040 |

0.4 |

0.6 |

3-3-3 Mechanical Performance:

|

Temper |

Tensile Strength N/mm2 |

Elongation ≥% |

Hardness HV |

|

|

M |

(O) |

≥295 |

40 |

—— |

|

Y4 |

(1/4H) |

390-510 |

35 |

100-160 |

|

Y2 |

(1/2H) |

440-570 |

10 |

160-205 |

|

Y |

(H) |

540-690 |

8 |

180-230 |

|

T |

(EH) |

≥640 |

5 |

≥200 |

Temper Mark:O. Soft;1/4H. 1/4 Hard;1/2H. 1/2 Hard;H. Hard;EH. Ultrahard.

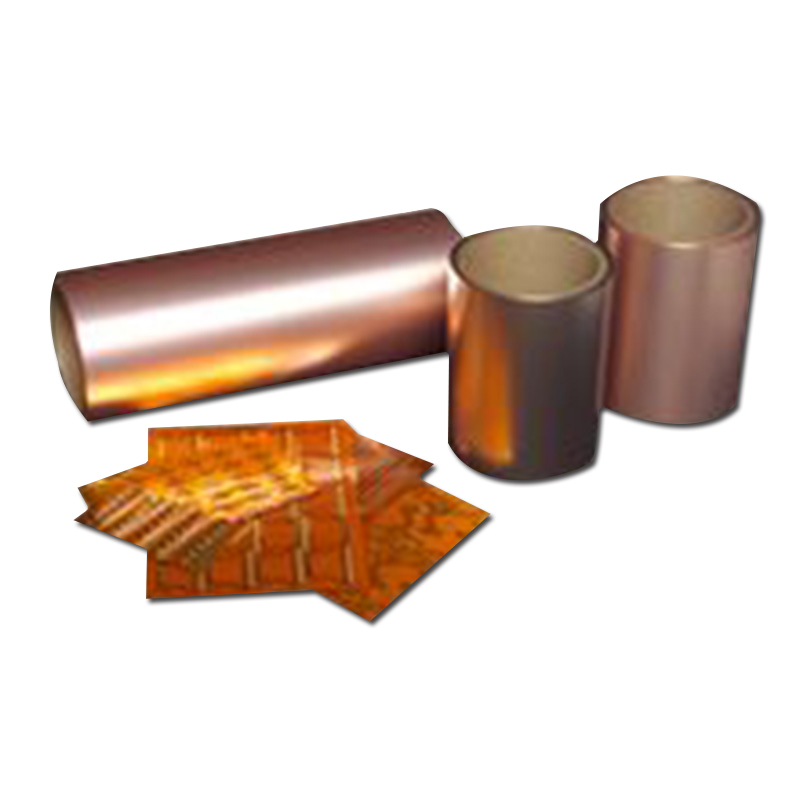

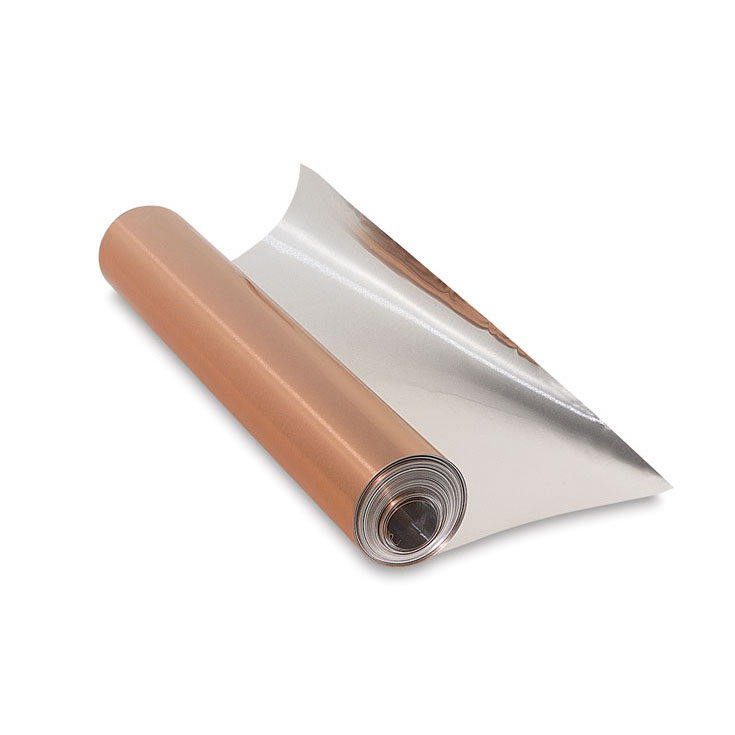

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for Factory directly supply Thin Brass Strips - Bronze Strip – CIVEN , The product will supply to all over the world, such as: Comoros, Turkey, Ecuador, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.