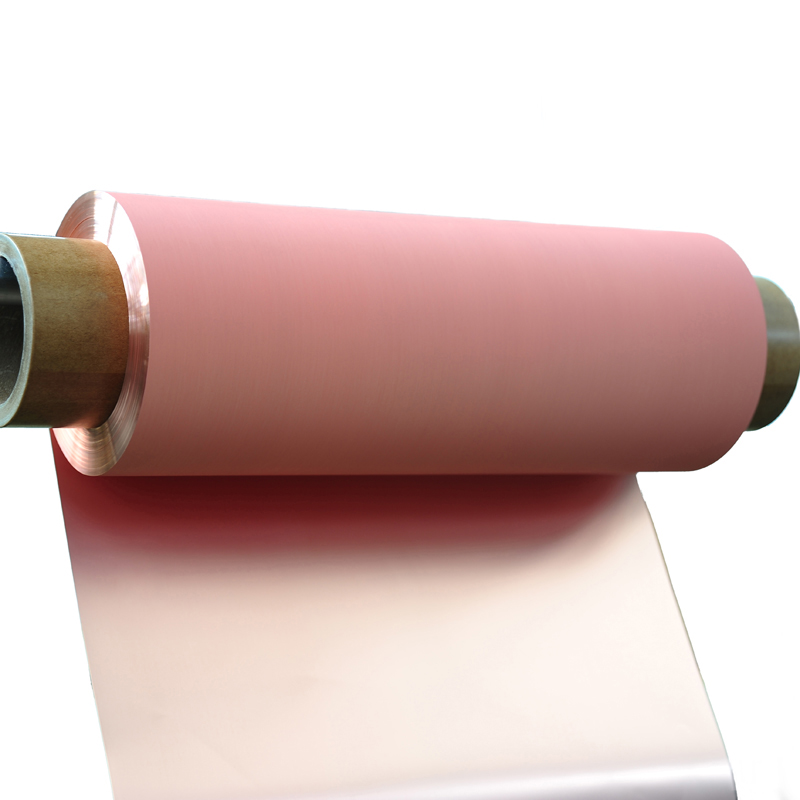

ED Copper Foils for Li-ion Battery (Double-matte)

Product Introduction

Electrodeposited Copper foil for single (double) sided gross lithium battery is a professional material produced by CIVEN METAL to improve the performance of battery negative electrode coating. The copper foil has a high purity, and after roughening process, it is easier to fit with the negative electrode material and less likely to fall off. CIVEN METAL can also custom slit the material to meet the requirements of different customers' products.

Specifications

CIVEN METAL can provide single (double) sided gross lithium copper foil of different widths from 8 to 12µm in nominal thickness.

Performance

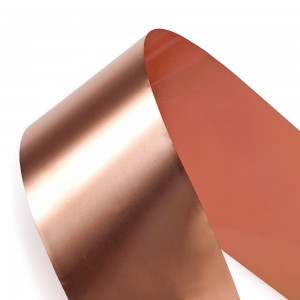

The product is formed with a columnar grain structure, the roughness of the glossy surface of the double-sided hairy lithium copper foil is rougher than that of the double-sided light lithium copper foil, and its elongation and tensile strength are lower than that of the double-sided light lithium copper foil, among other properties (see Table 1).

Applications

It can be used as anode carrier and collector for lithium-ion batteries.

Advantages

Single (double) side lithium copper foil light (hair) surface is rougher than double-sided light lithium copper foil, its bond with the negative electrode material is more solid, not easy to fall out of the material, and the match with the negative electrode material is strong.

|

Test Item |

Unit |

Specification |

||||||

|

Single-Matte |

Double-Matte |

|||||||

|

8μm |

9μm |

10μm |

12μm |

9μm |

10μm |

12μm |

||

|

Area Weight |

g/m2 |

70-75 |

85-90 |

95-100 |

105-110 |

85-90 |

95-100 |

105-110 |

|

Tensile Strength |

Kg/mm2 |

≥28 |

||||||

|

Elongation |

% |

≥2.5 |

≥3.0 |

|||||

|

Roughness(Rz) |

μm |

Conference of parties |

||||||

|

Thickness |

μm |

Conference of parties |

||||||

|

Change of Color |

(130℃/10min) |

No change |

||||||

|

Width Tolerance |

mm |

-0/+2 |

||||||

|

Appearance |

---- |

1. The copper foil surface is smooth and level off.2. No obvious concave and convex point, crease, indentation, damage.

3. The color and luster is uniform, no oxidation, corrosion and oil. 4. Trimming flush, no lace and copper powder. |

||||||

|

Joint |

---- |

No more than 1 joint per roll |

||||||

|

Cu Content |

% |

≥99.9 |

||||||

|

Environment |

---- |

RoHS Standard |

||||||

|

Shelf Life |

---- |

90 days after received |

||||||

|

Weight of Roll |

kg |

Conference of parties |

||||||

|

Packing |

---- |

Indicated on the package with item name, specification, batch number, net weight, gross weight, RoHS and manufacturers | ||||||

|

Storage Condition |

---- |

1. The warehouse should keep clean, dry, and humidity is under 60% as well as The temperature under 25 ℃.2. The warehouse should be no corrosive gas, chemicals and wet goods. | ||||||

Table 1. Performance

Note: 1. Copper foil oxidation resistance performance and surface density index can be negotiated.

2. The performance index is subject to our testing method.

3. The quality guarantee period is 90 days from the date of receipt.